Product Categories

Contact Us

Add:Building 8, International Financial Center, Liaocheng Economic and Technological Development Zone, Shandong Province, China

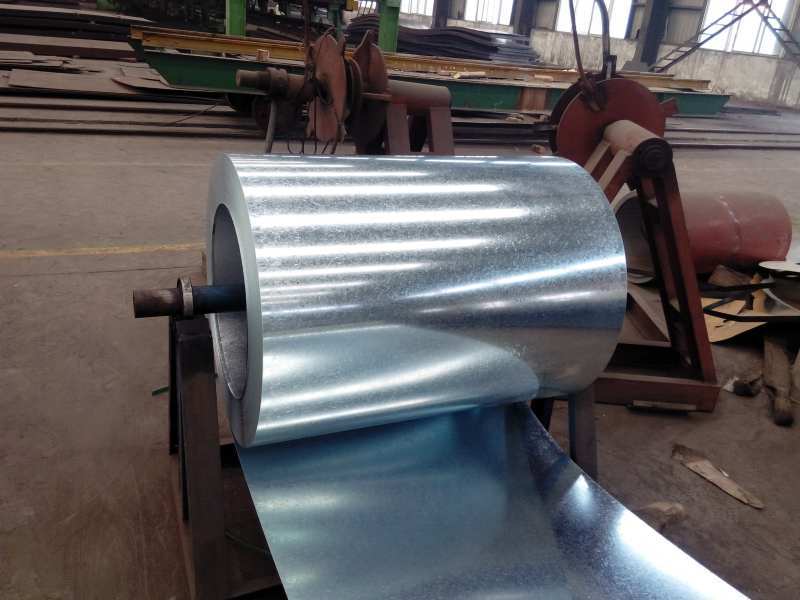

Color Coated Galvalume Roof Sheet PPGL

PPGL roof panels are an excellent building material. Its weight is only 1/30 of the traditional concrete roof, which is easy to install and greatly shortens the construction period. It also maintains the strength and durability of the steel, allowing it to last more than 25 years under normal conditions. In addition, it is beautiful and generous, with various colors, patterns and patterns, which can meet different architectural styles. More importantly, PPGL steel has excellent heat resistance, which makes it an ideal roofing material even in hot climates. Whether it is home or investment, PPGL roof panels will be a good choice.

Keywords:

Description

Color Coated Galvalume Roof Sheet PPGL Description

PPGL roof panels are an excellent building material. Its weight is only 1/30 of the traditional concrete roof, which is easy to install and greatly shortens the construction period. It also maintains the strength and durability of the steel, allowing it to last more than 25 years under normal conditions. In addition, it is beautiful and generous, with various colors, patterns and patterns, which can meet different architectural styles. More importantly, PPGL steel has excellent heat resistance, which makes it an ideal roofing material even in hot climates. Whether it is home or investment, PPGL roof panels will be a good choice.

Product Parameters

| Product Name | Color Coated Galvalume Roof Sheet PPGL |

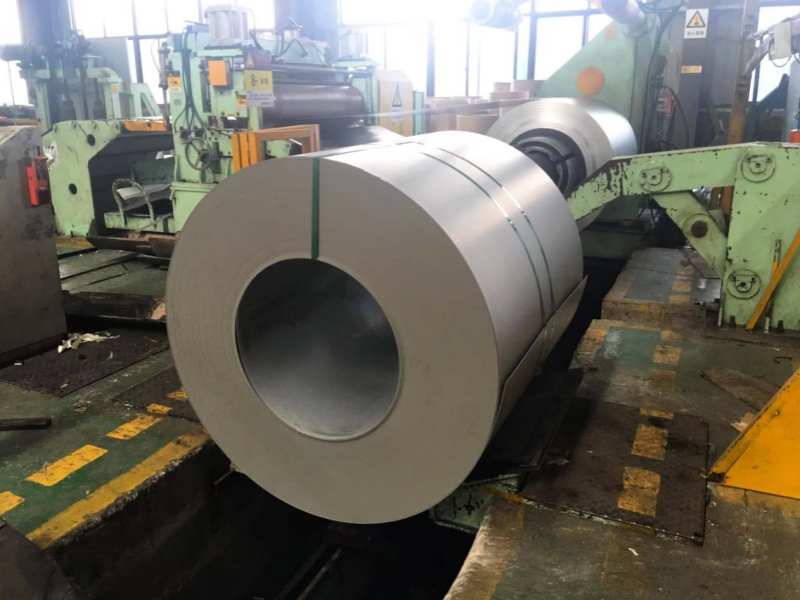

| Type | Steel Coil |

| Thickness | 0.12~2.0 mm |

| Width | 600 mm~1500 mm |

| Zn Coating | 0.13-0.8 mm is 30-150 g/㎡; 0.8-1.5 mm is 30-180 g/㎡; 1.5-6.0 mm is 30-275 g/㎡ |

| Coil Weight | 3-6mt |

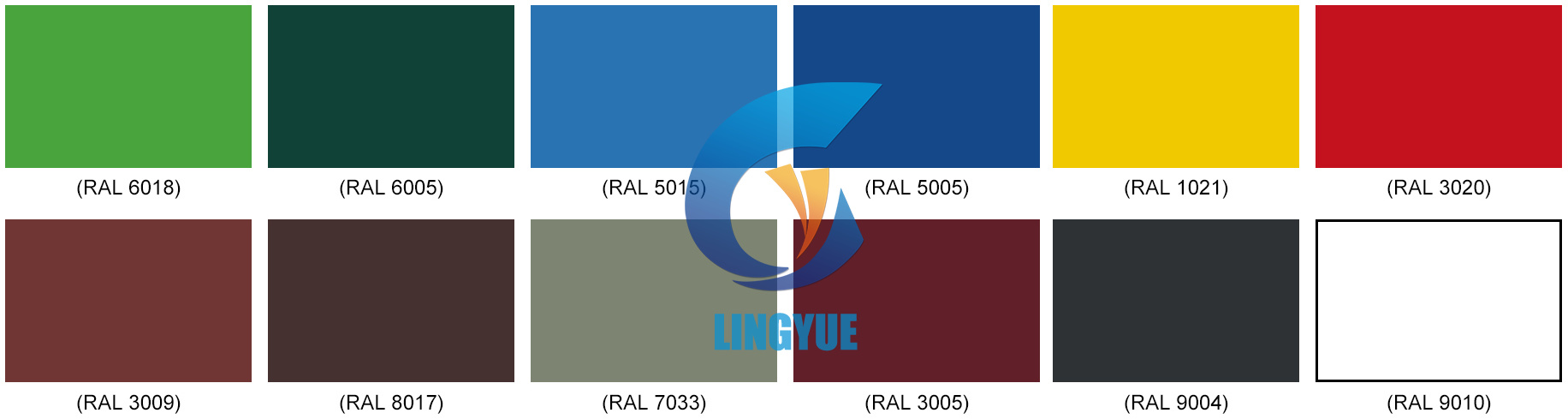

| Colors | RAL Colors or as customer requirements |

| Surface treatment | Top paint: FVDF, HDP, SMP, PE, PU |

| Prime paint: polyurethane, epoxy, PE | |

| Back paint: epoxy, modified polyester | |

| Standard | ASTM, JIS, EN |

| Certificate | ISO, CE |

| Delivery times | 8-15 days after the receipt of deposit |

| Package | tied up with steel strips and wrapped with water proof paper |

| Loading port | Qingdao, China |

| Application | Widely used in roofing sheet, window-shades, car ceiling, the shell of the car, air conditioner, outer shell of water machine etc. |

Product Specifications

| Type | Thickness(mm) | Width(mm) | |||

| 1219 | 1500 | 1800 | 2000 | ||

| Cold Rolled | 0.3 | √ | √ | √ | √ |

| 0.4 | √ | √ | √ | √ | |

| 0.5 | √ | √ | √ | √ | |

| 0.6 | √ | √ | √ | √ | |

| 0.7 | √ | √ | √ | √ | |

| 0.8 | √ | √ | √ | √ | |

| 0.9 | √ | √ | √ | √ | |

| 1.0 | √ | √ | √ | √ | |

| 1.2 | √ | √ | √ | √ | |

| 1.5 | √ | √ | √ | √ | |

| 1.8 | √ | √ | √ | √ | |

| 2.0 | √ | √ | √ | √ | |

| 2.5 | √ | √ | √ | √ | |

| 3.0 | √ | √ | √ | √ | |

| 4.0 | √ | √ | √ | √ | |

| 5.0 | √ | √ | √ | √ | |

| 6.0 | √ | √ | √ | √ | |

| Hot Rolled | 4.0 | √ | √ | √ | √ |

| 5.0 | √ | √ | √ | √ | |

| 6.0 | √ | √ | √ | √ | |

| 8.0 | √ | √ | √ | √ | |

| 10.0 | √ | √ | √ | √ | |

| 12.0 | √ | √ | √ | √ | |

| 14.0 | √ | √ | √ | √ | |

| 16.0 | √ | √ | √ | √ | |

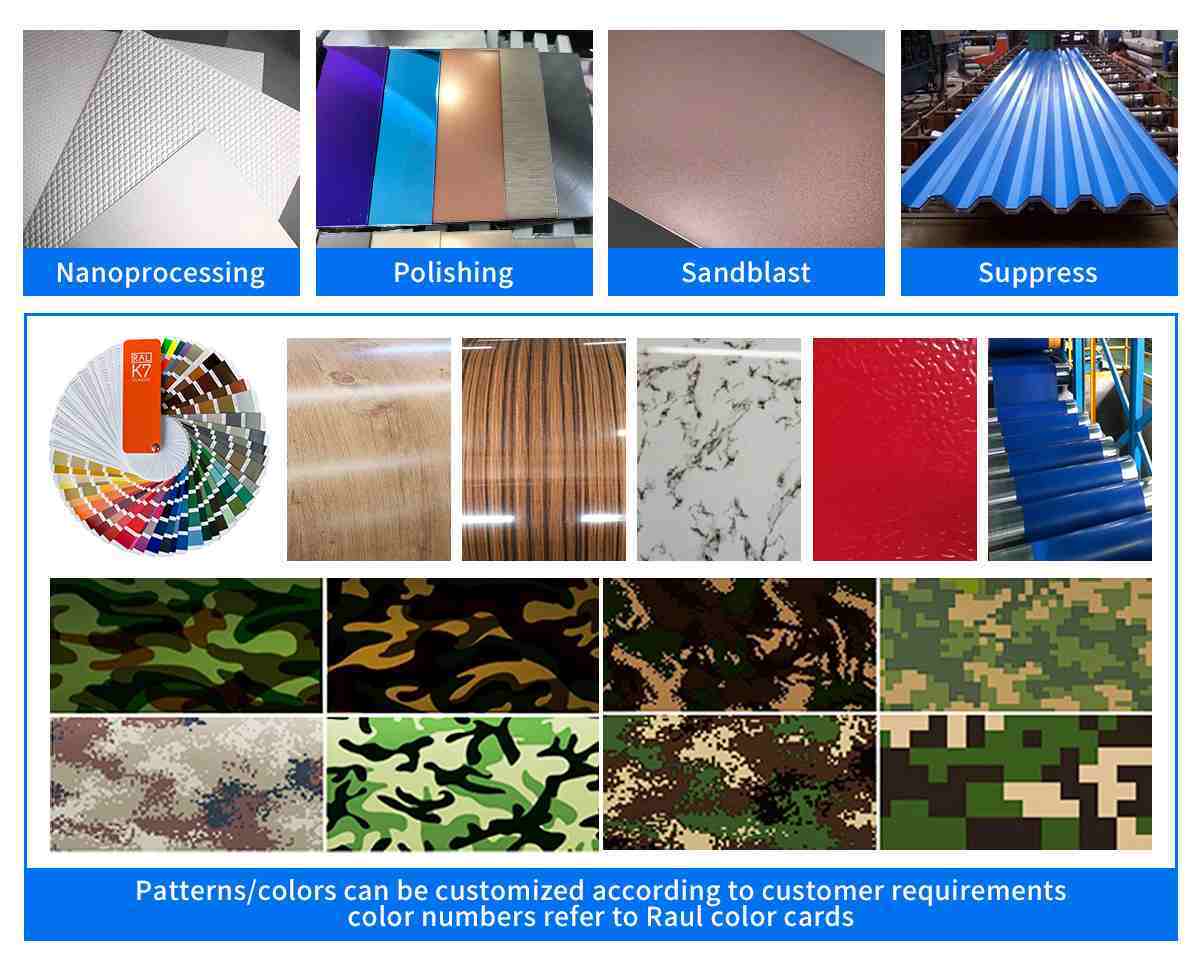

Color Selection

We provide many colors to choose from, the following are common colors, if you like other colors or patterns, please send us the RAL color code.

Advantages of Color Coated Plate

Custom Colors

You can choose any RAL color, as well as customize the pattern according to your needs. The beautiful surface makes the color coated board decorative. So it can be directly used in many fields.

Tough Soating

Color coated steel plate including PPGL plate PPGI steel, the use of continuous coil coating, the surface luster bright, no cracking, no peeling. In addition, it can keep the color for at least 10 years.

Excellent Mechanical Properties

The color coated plate retains the mechanical properties of the base metal, such as tensile strength. In addition, the application of the coating can protect the surface from rust, thereby extending its service life. Studies have shown that the service life of color-coated steel sheets is 50% longer than that of galvanized steel sheets.

Easy to Use

Different from the coil, the color coated plate is a kind of finished product. This means that it can be directly used in many industries. Considering its light weight, it is easy to carry and install. In addition, due to its aesthetic appearance, no additional decoration is required. Also, less maintenance is required during the service life.

Coating Type

In the coil coating, the durability of the role is the resin and pigment, the most commonly used finish polyester, silicon modified polyester, high durability polyester and polyvinylidene fluoride.

Polyester PE

Good adhesion, rich color, wide range in formability and outdoor durability, medium chemical resistance, low cost.

Silicon Modified Polyester SMP

The hardness, abrasion resistance and heat resistance of the coating film are good; as well as good external durability and powder resistance, gloss retention, general flexibility and medium cost.

High Durability Polyester HDP

Excellent color retention and UV resistance, excellent outdoor durability and chalking resistance, good film adhesion, rich color, excellent cost performance.

Polyvinylidene Fluoride PVDF

Excellent color retention and UV resistance, excellent outdoor durability and chalking resistance, excellent solvent resistance, good formability, dirt resistance, limited color, and high cost.

| Product Details | Product Production | Product Warehouse |

|

|

|

|

|

|

Applications

PPGI Purpose:

1. Construction field: Color coated steel coils are widely used in fields such as building roofs, wall panels, doors and windows, roof trusses, partitions, and ceilings. Color coated steel coils not only have aesthetic properties, but also have good waterproof, fireproof, and thermal insulation properties, making them an excellent building material.

2. Home appliance field: Color coated steel coils are widely used in making home appliance shells, such as refrigerators, air conditioners, washing machines, microwaves, and electric ovens. Color coated steel coils have characteristics such as wear resistance, corrosion resistance, easy cleaning, and aesthetics, which can meet the appearance and performance requirements of the home appliance industry.

3. Transportation field: Color coated steel coils can be used to make components such as body shells, roof, chassis, and frame. Color coated steel coils have the characteristics of lightweight, high strength, corrosion resistance, wear resistance, and aesthetics, which can improve the safety and aesthetics of transportation vehicles.

4. Furniture field: Color coated steel coils can be used to make furniture such as office furniture, kitchen furniture, bookshelves, and wardrobes. Color coated steel coils have the characteristics of aesthetics, wear resistance, easy cleaning, and corrosion resistance, which can meet the requirements of the furniture industry for material appearance and performance.

5. Electronic equipment field: Color coated steel coils can be used to make electronic equipment casings such as television casings, audio casings, and computer casings. Color coated steel coils have the characteristics of aesthetics, wear resistance, corrosion resistance, and electromagnetic interference resistance, which can improve the safety and aesthetics of electronic equipment.

Project Cases

Additional Processing Technology

PPGI can customize patterns/colors according to customer requirements, with color codes referring to the Raul color card

Product Packaging

Product Transportation

Corporate Honor

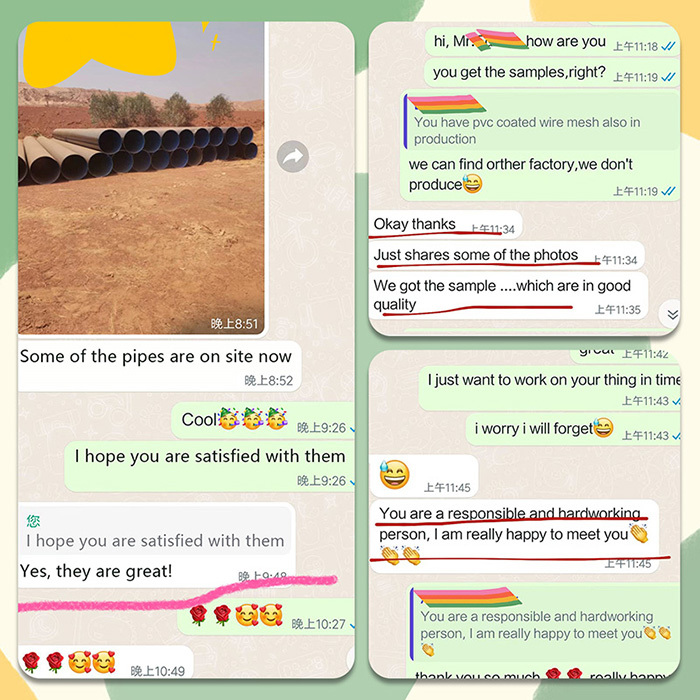

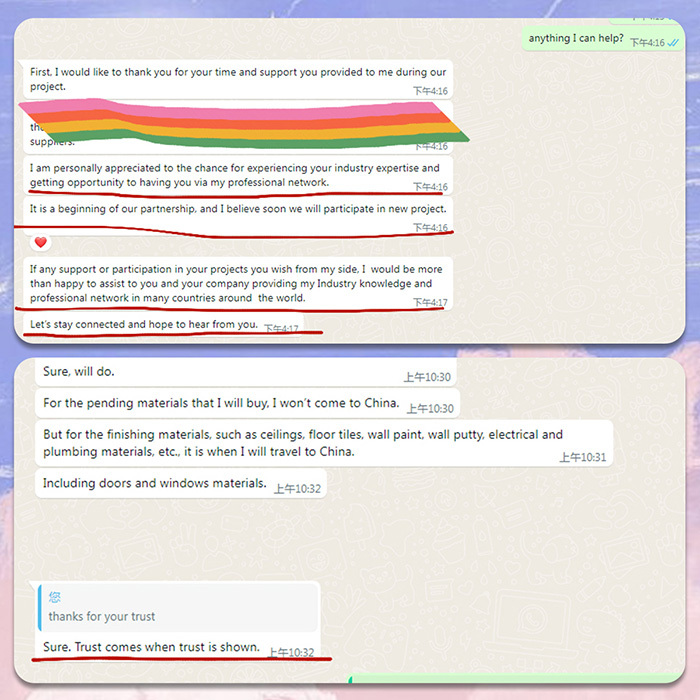

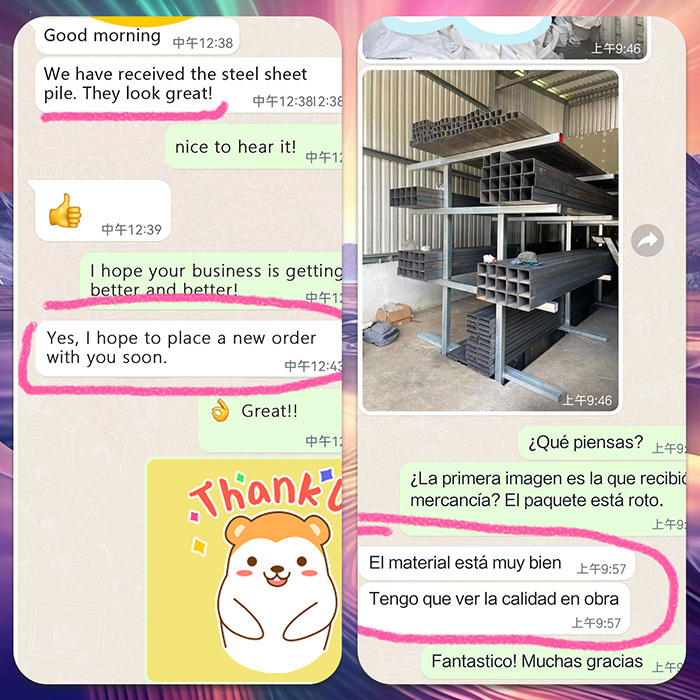

Client Feedback

FAQ

...

Get a free quote

Please fill in the contact information with your needs, we will arrange a professional to contact you!