Categories

Products

Silicon steel is a silicon alloy steel containing 1.0–4.5% silicon and less than 0.08% carbon. It possesses characteristics such as high magnetic permeability, low coercivity, and high resistivity, resulting in low hysteresis and eddy current losses. It is mainly used as a magnetic material in motors, transformers, electrical appliances, and electrical instruments. To meet the requirements of punching and shearing processes during electrical manufacturing, a certain degree of plasticity is also required. To improve magnetic performance and reduce hysteresis losses, the content of harmful impurities should be as low as possible, and the sheet should be flat with good surface quality.

Cold Rolled Grain Oriented Silicon Steel Strip Coils

Oriented grain electrical steel, also known as cold-rolled grain-oriented silicon steel, refers to cold-rolled electrical steel containing 2.9% to 3.5% Si, with a regular and oriented crystal structure. Electrical steel, also called silicon steel sheet, is an essential soft magnetic alloy for the power, electronics, and military industries, and is also the most produced functional metal material, mainly used as the core of various motors, generators, and transformers.

Silicon Steel Strip Coils Non-Oriented

Non-oriented silicon steel: A silicon-iron alloy with very low carbon content. In the deformed and annealed steel sheet, its grains exhibit an irregular orientation distribution. The silicon content of the alloy is 1.5%–3.0%, or the combined silicon and aluminum content is 1.8%–4.0%. The product is typically cold-rolled sheet or strip with nominal thicknesses of 0.35 and 0.5 mm, mainly used in the manufacture of electric motors and generators.

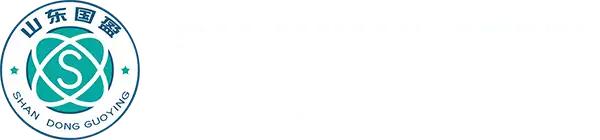

Spring Steel 65Mn Cold Rolled Steel Strip Slit Coils

Cold-rolled strip steel has various product specifications, high dimensional accuracy, good surface quality, and better mechanical and process properties than hot-rolled strip steel. Therefore, it is widely used in industrial sectors such as machinery manufacturing, automobile manufacturing, building structures, electronic instruments and household appliances.

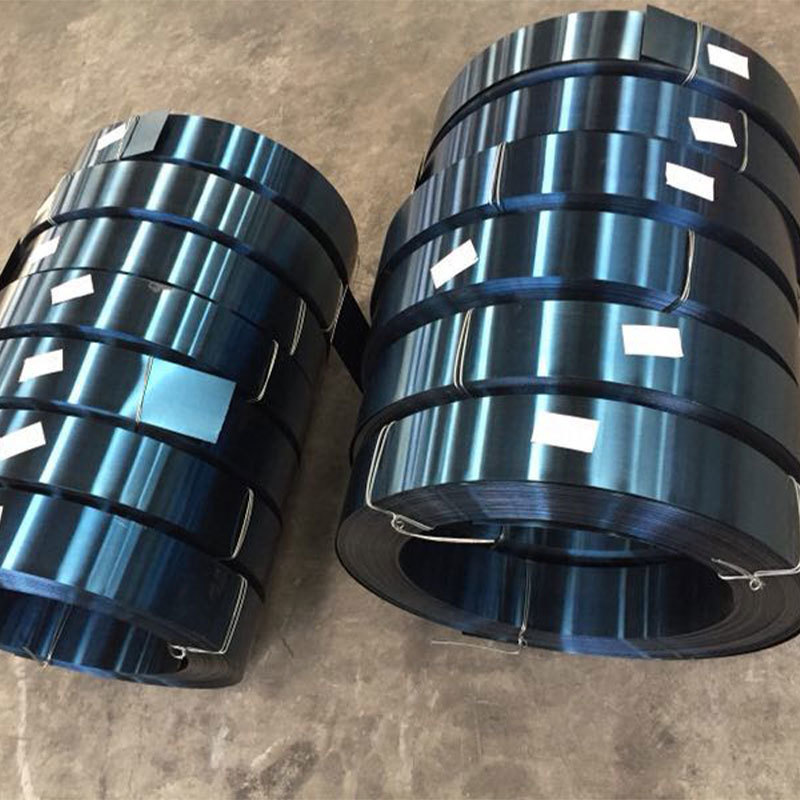

Black steel strap are widely used in industrial packaging, such as bundling and fixing in the wood, paper, steel, chemical fiber and other industries, as well as in the manufacture of rolling shutter doors. This type of steel strapping is corrosion-resistant and easy to operate, which can effectively improve logistics and transportation efficiency.

Baked blue strip (also known as baked blue steel strip) is a metal material that is oxidized at high temperature. It is mainly used for bundling goods,manufacturing tools, springs and washers, fasteners, cutting tools, etc., specific blue black appearance industrial parts or consumer accessories are required.And has high strength, corrosion resistance and high temperature resistance. It is commonly used in logistics, warehousing, steel industry and other scenarios.

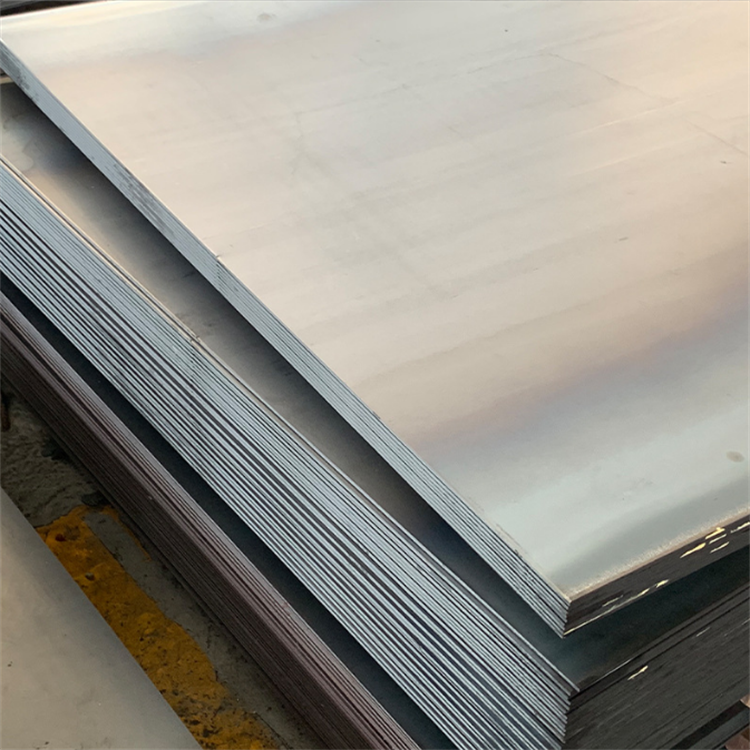

Hot rolled strip steel is widely used in the automotive, motor, chemical, shipbuilding and other industrial sectors, and is also used as billet for cold rolling, welded pipes and cold-bent steel production. It has the advantages of high production efficiency, high output and good quality.

Galvanized steel strip is a steel strip material that has been galvanized. It has good corrosion resistance and a long service life. Its surface is covered with a layer of zinc, which can prevent the steel strip from being damaged by oxidation and corrosion. Galvanized steel strip is widely used in many industries such as construction, automobiles, home appliances, electronics, etc.

Galvanized steel strip is a steel strip material that has been galvanized. It has good corrosion resistance and a long service life. Its surface is covered with a layer of zinc, which can prevent the steel strip from being damaged by oxidation and corrosion. Galvanized steel strip is widely used in many industries such as construction, automobiles, home appliances, electronics, etc.

It has high tensile strength, plasticity and toughness, and is non-magnetic. Even if the parts are worn to a very thin layer, they can still withstand large impact loads without breaking. It can be used to cast various impact-resistant wear parts, etc.

HSS is a tool steel with high hardness, high wear resistance and high heat resistance, also known as high-speed tool steel or high-speed steel. High-speed steel has good processing performance and good strength and toughness, so it is mainly used to make complex thin-blade and impact-resistant metal cutting tools.