Categories

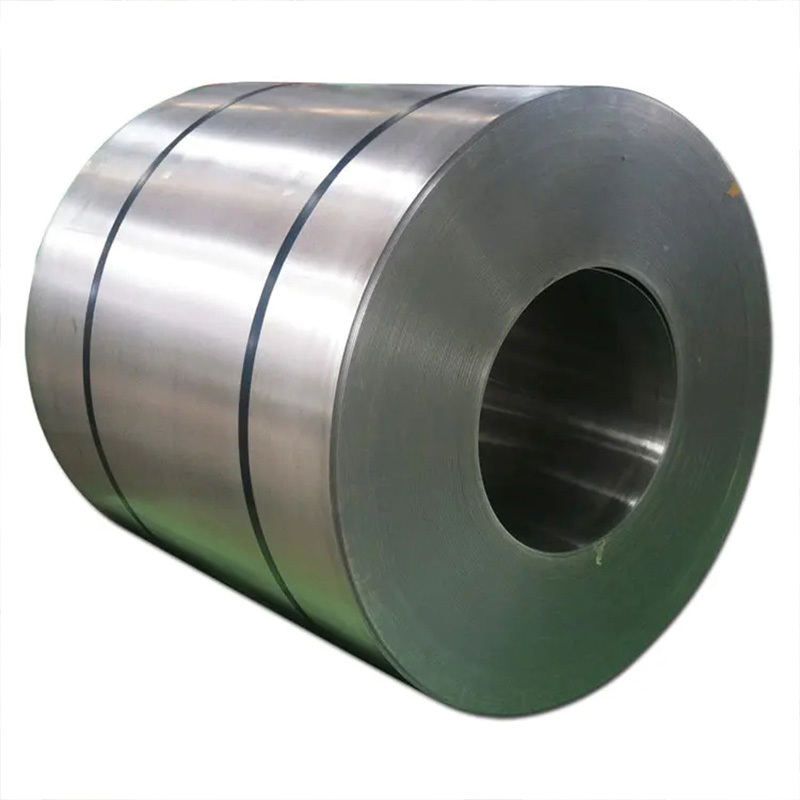

Steel Coil

GB/T700 GB/T1591 GB Material Carbon Steel Coil

GB/T700 Q275 carbon steel and low alloy steel coil equivalent material is S275JR steel plate. S275JR steel coil is a general purpose carbon structural steel. This steel is similar to the steels listed in China GB/T700 and GB/T1591. It is also a carbon structural steel and low alloy structural steel used in engineering steel and structural steel, which is usually not heat treated. GB/T1591 steel coil is a Chinese standardized low alloy medium tensile strength steel coil produced by hot rolling process. GB/T1591 steel coil has a variety of manufacturing purposes.

EN10025-2 S235/S275/S355 Carbon Steel Coil

EN10025-2 steel coil is a low-alloy high-strength structural steel, which is made of carbon structural steel (Wc = 0.16%~ 0.2%) by adding a small amount of alloying elements. EN10025-2 steel coil has good welding performance, plasticity, toughness and processing technology, good corrosion resistance, high strength and low cold brittle critical transition temperature.

Hot dip galvanizing is to make the molten metal react with the iron substrate to produce an alloy layer, so that the substrate and the coating are combined. Hot galvanizing is to pickle the steel and iron parts first. In order to remove the iron oxide on the surface of the steel and iron parts, after pickling, it is cleaned by ammonium chloride or zinc chloride aqueous solution or ammonium chloride and zinc chloride mixed aqueous solution tank, and then sent into the hot dip plating tank. Hot-dip galvanizing has the advantages of uniform coating, strong adhesion and long service life.

Hot-dip galvanizing is one of the effective means to delay the environmental corrosion of iron and steel materials, it is the surface of the cleaned, activated iron and steel products immersed in molten zinc, through the reaction and diffusion between iron and zinc, in the iron and steel products surface plating good adhesion of zinc alloy coating. Compared with other metal protection methods, the hot-dip galvanizing process has advantages in the protection characteristics of the combination of physical barrier and electrochemical protection of the coating, the bonding strength of the coating and the substrate, the compactness, durability, maintenance-free and economy of the coating, and its adaptability to the shape and size of the product. At present, hot-dip galvanized products mainly include steel plates, steel strips, steel wires, steel pipes, etc., of which hot-dip galvanized steel plates account for a large proportion.

The material of DX51D galvanized sheet is a non-ferrous alloy with zinc as the matrix and other elements. The main alloying elements are aluminum, copper, magnesium and so on. Zinc alloy has low melting point, good fluidity, easy plastic processing and welding, and resistance to atmospheric corrosion.

According to the manufacturing process, it is divided into cast zinc alloy and deformed zinc alloy. The commonly used casting zinc alloy is zinc-aluminum-copper-magnesium alloy, which has good casting process performance, and the cooling rate has little effect on the mechanical properties. They are mainly used in the manufacture of mechanical parts, toys, decorations and household appliances.

304 stainless steel is a kind of universal stainless steel material, rust resistance than 200 series of stainless steel material is stronger. High temperature resistance is also better, can be as high as 1000-1200 degrees. 304 stainless steel has excellent corrosion resistance and good intergranular corrosion resistance. For oxidizing acids, it is concluded in the experiment that 304 stainless steel has strong corrosion resistance in nitric acid with a concentration of less than or equal to 65% of the boiling temperature. It also has good corrosion resistance to alkali solution and most organic and inorganic acids.

Type 201 stainless steel is an austenitic chromium-nickel-manganese stainless steel, which is developed to save nickel. Type 201 is a low-cost alternative to traditional Cr-Ni stainless steels such as 301 and 304. The nickel is replaced by added manganese and nitrogen. It cannot be hardened by heat treatment, but can reach high tensile strength by cold working. Type 201 is essentially non-magnetic in the annealed condition and becomes magnetic upon cold working. In many applications, the 201 type may replace the 301 type.

Silicon steel coil oriented and non-oriented electrical steel

Silicon steel is a ferrosilicon alloy with a silicon content of about 3% and the rest mainly iron. It is an indispensable and important soft magnetic alloy in electricity, electronics and it is also the largest metal functional material. It is mainly used as the core of various motors, generators and transformers. Its production process is complex and the manufacturing process is strict. Foreign production technology is protected in the form of patents and is regarded as the life of the enterprise.

China supply silicon steel coil sheet used in the manufacture of transformers and motors

Silicon steel is a ferrosilicon alloy with a silicon content of about 3% and the rest mainly iron. It is an indispensable and important soft magnetic alloy in electricity, electronics and it is also the largest metal functional material. It is mainly used as the core of various motors, generators and transformers. Its production process is complex and the manufacturing process is strict. Foreign production technology is protected in the form of patents and is regarded as the life of the enterprise.

China factories supply grain-oriented and non-grain-oriented silicon steel coil

Silicon steel is a ferrosilicon alloy with a silicon content of about 3% and the rest mainly iron. It is an indispensable and important soft magnetic alloy in electricity, electronics and it is also the largest metal functional material. It is mainly used as the core of various motors, generators and transformers. Its production process is complex and the manufacturing process is strict. Foreign production technology is protected in the form of patents and is regarded as the life of the enterprise.

Silicon steel is a ferrosilicon alloy with a silicon content of about 3% and the rest mainly iron. It is an indispensable and important soft magnetic alloy in electricity, electronics and it is also the largest metal functional material. It is mainly used as the core of various motors, generators and transformers. Its production process is complex and the manufacturing process is strict. Foreign production technology is protected in the form of patents and is regarded as the life of the enterprise.

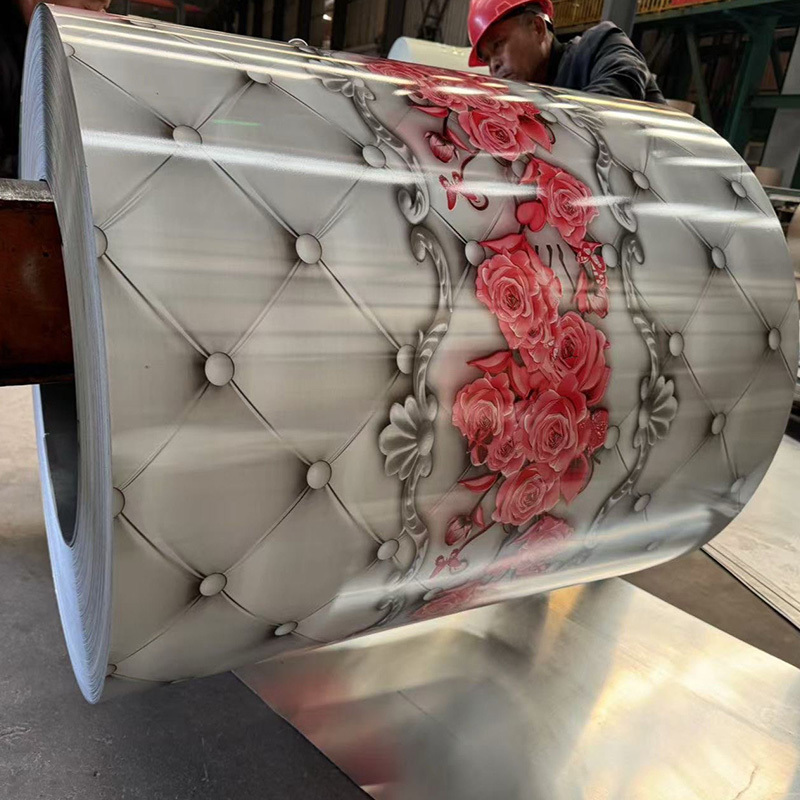

Alu-Zinc coating:150gsm PPGL is a hot-dip aluminum-zinc plate as the substrate, after surface pretreatment, roller coating method, coated with one or more layers of liquid coating, after baking and cooling, the surface is rich in color, good weather resistance, superior processing performance.

Color coated board can be divided into ordinary PE, high corrosion resistant HDP, high corrosion resistant silicon modified polyester SMP, high corrosion resistant fluorocarbon PVDF, super corrosion resistant nano fluorocarbon PVDF, aluminum magnesium manganese color coated board, printing color coated board, etc.

The varieties that can be produced are: ordinary building materials board, purification board, cold storage board, solar panel, door and window profile, household appliance board, writing board, printing board, reticulated suede color coating, embossed printing, aluminum magnesium manganese color coating board, high weather resistance, silicon modification, self-cleaning board, heat reflection board, antibacterial board, acid and alkali resistant color coating board, etc., which can meet customer requirements of different industries and provide technical support and solutions.

Color Coated Galvalume Steel Sheet PPGL

Color-coated galvanized sheet PPGL is a hot-dip aluminum-zinc plate as the substrate, after surface pretreatment, roller coating method, coated with one or more layers of liquid coating, after baking and cooling, the surface is rich in color, good weather resistance, superior processing performance.

Color coated board can be divided into ordinary PE, high corrosion resistant HDP, high corrosion resistant silicon modified polyester SMP, high corrosion resistant fluorocarbon PVDF, super corrosion resistant nano fluorocarbon PVDF, aluminum magnesium manganese color coated board, printing color coated board, etc.

The varieties that can be produced are: ordinary building materials board, purification board, cold storage board, solar panel, door and window profile, household appliance board, writing board, printing board, reticulated suede color coating, embossed printing, aluminum magnesium manganese color coating board, high weather resistance, silicon modification, self-cleaning board, heat reflection board, antibacterial board, acid and alkali resistant color coating board, etc., which can meet customer requirements of different industries and provide technical support and solutions.