Categories

Steel Profiles

Hot-dip galvanized channel steel is also called hot-dip galvanized channel steel and hot-dip galvanized channel steel. It is an effective metal anti-corrosion method and is mainly used in metal structural facilities in various industries. It is to immerse the channel steel after derusting in the molten zinc of about 440~460 ℃, so that the zinc layer is attached to the surface of the channel steel, thus achieving the purpose of anti-corrosion. Now the main method of galvanizing the surface of the channel steel is hot dip galvanizing.

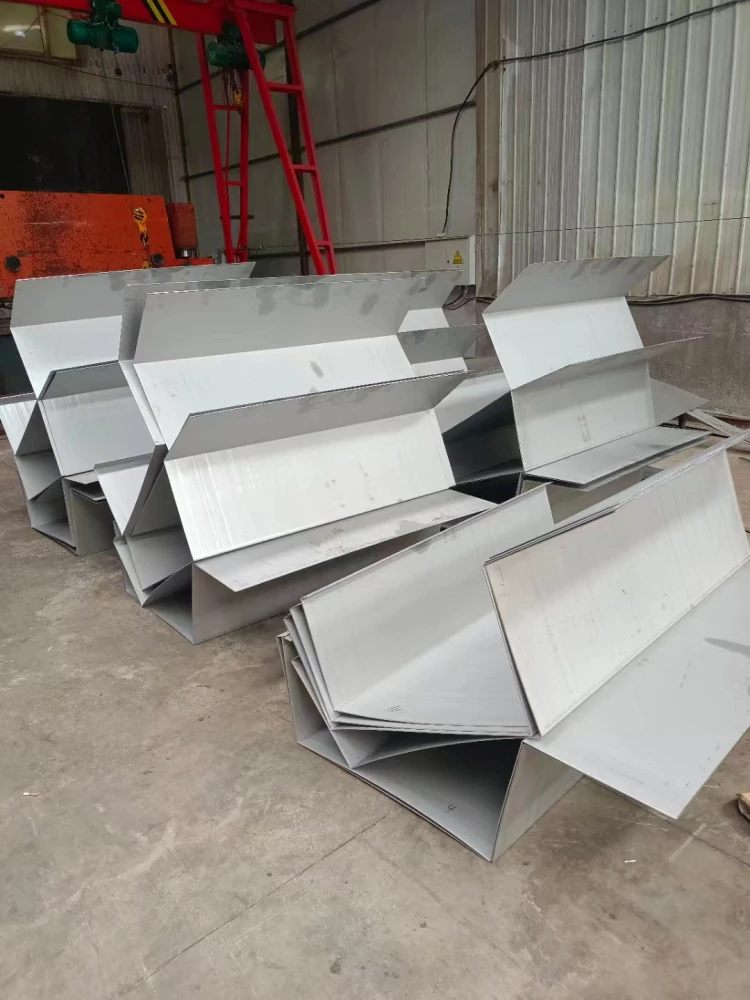

Stainless Steel C Groove Steel

The stainless steel channel is a long strip steel whose cross-sectional shape is a groove shape. Same as I-beam, stainless steel channel steel is also divided into two kinds of ordinary channel steel and light channel steel. The main purpose of hot-rolled stainless steel ordinary channel steel is: ordinary channel steel is mainly used for building structure, vehicle manufacturing and other industrial structures, and is often used in conjunction with I-beam.

Hot-rolled stainless steel light channel steel (YB164-63) Hot-rolled light channel steel is a kind of steel with wide legs and thin walls, which has better economic effect than ordinary hot-rolled channel steel. Main uses: construction and steel frame structure, etc.

The stainless steel channel is a long strip steel whose cross-sectional shape is a groove shape. Same as I-beam, stainless steel channel steel is also divided into two kinds of ordinary channel steel and light channel steel. The main purpose of hot-rolled stainless steel ordinary channel steel is: ordinary channel steel is mainly used for building structure, vehicle manufacturing and other industrial structures, and is often used in conjunction with I-beam.

Hot-rolled stainless steel light channel steel (YB164-63) Hot-rolled light channel steel is a kind of steel with wide legs and thin walls, which has better economic effect than ordinary hot-rolled channel steel. Main uses: construction and steel frame structure, etc.

Stainless steel I-beams are made of 201(1Cr17Ni5Mn6N), 202(2 Cr13Mn9Ni4), 301(1 Cr17Ni7), 303(Y1Cr18Ni9), 304(OCr18Ni9), 304L (03 Cr19Ni10), 316(0 Cr17Ni12Mo2), 316L(00 Cr17Ni14Mo2), 321 (1 Cr18Ni9Ti), 420( 2cr13), 310S(0 Cr25Ni20), etc. The chemical composition of stainless steel I-beams belongs to general structural rolled steel series, the main test indexes were C, Mn, P and S. According to different grades, the content varies, the approximate range is C<0.08%, Mn: 2.0, P<0.035%, S<0.03%. Materials are widely used in hardware products, medical machinery, food machinery, ships, automobiles, doors and windows, furniture, large machinery, etc.

Stainless steel I-beams are made of 201(1Cr17Ni5Mn6N), 202(2 Cr13Mn9Ni4), 301(1 Cr17Ni7), 303(Y1Cr18Ni9), 304(OCr18Ni9), 304L (03 Cr19Ni10), 316(0 Cr17Ni12Mo2), 316L(00 Cr17Ni14Mo2), 321 (1 Cr18Ni9Ti), 420( 2cr13), 310S(0 Cr25Ni20), etc. The chemical composition of stainless steel I-beams belongs to general structural rolled steel series, the main test indexes were C, Mn, P and S. According to different grades, the content varies, the approximate range is C<0.08%, Mn: 2.0, P<0.035%, S<0.03%. Materials are widely used in hardware products, medical machinery, food machinery, ships, automobiles, doors and windows, furniture, large machinery, etc.

Product Description

Stainless steel I-beams are made of 201(1Cr17Ni5Mn6N), 202(2 Cr13Mn9Ni4), 301(1 Cr17Ni7), 303(Y1Cr18Ni9), 304(OCr18Ni9), 304L (03 Cr19Ni10), 316(0 Cr17Ni12Mo2), 316L(00 Cr17Ni14Mo2), 321 (1 Cr18Ni9Ti), 420( 2cr13), 310S(0 Cr25Ni20), etc. The chemical composition of stainless steel I-beams belongs to general structural rolled steel series, the main test indexes were C, Mn, P and S. According to different grades, the content varies, the approximate range is C<0.08%, Mn: 2.0, P<0.035%, S<0.03%. Materials are widely used in hardware products, medical machinery, food machinery, ships, automobiles, doors and windows, furniture, large machinery, etc.

H-beam is a new type of steel for economic construction. H-beam has economical and reasonable cross-sectional shape, good mechanical properties, uniform extension of each point on the cross-section and small internal stress during rolling. Compared with ordinary I-beam, H-beam has the advantages of large cross-sectional modulus, light weight and metal saving, which can reduce the building structure by 30-40%. In addition, because its legs are parallel to the inner and outer sides and the leg ends are right angles, the welding and riveting work can be saved by 25%. It is often used in large buildings (such as factories, high-rise buildings, etc.) with large bearing capacity and good cross-sectional stability, as well as bridges, ships, lifting and transportation machinery, equipment foundations, supports, foundation piles, etc.

Galvanized H-beam is a cross-sectional area distribution is more optimized, more reasonable than the economic section of high-efficiency profiles, because of its section and the English letter "H" the same name. Since all parts of the H-beam are arranged at right angles, the H-beam has the advantages of strong bending resistance, simple construction, cost saving and light structure in all directions, and has been widely used.

H-beam is a more optimized cross-sectional area distribution, more reasonable than the economic section of high-efficiency profiles, because of its section and the English letter "H" the same name. Since all parts of the H-beam are arranged at right angles, the H-beam has the advantages of strong bending resistance, simple construction, cost saving and light structure in all directions, and has been widely used.