Categories

Steel Coil

Color Coated Galvalume Steel Sheet PPGL

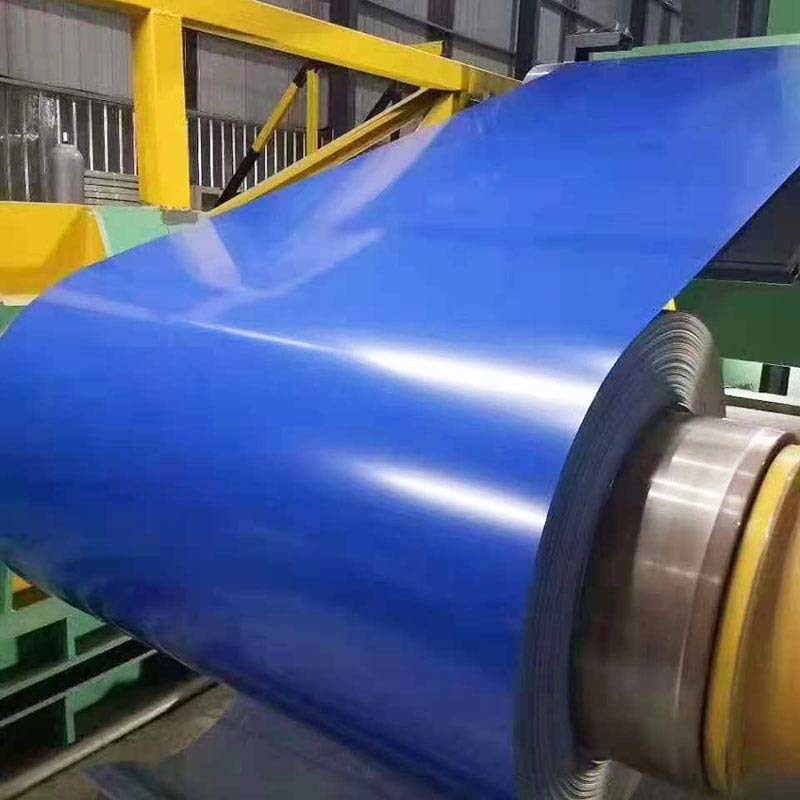

Color-coated galvanized sheet PPGL is a hot-dip aluminum-zinc plate as the substrate, after surface pretreatment, roller coating method, coated with one or more layers of liquid coating, after baking and cooling, the surface is rich in color, good weather resistance, superior processing performance.

Color coated board can be divided into ordinary PE, high corrosion resistant HDP, high corrosion resistant silicon modified polyester SMP, high corrosion resistant fluorocarbon PVDF, super corrosion resistant nano fluorocarbon PVDF, aluminum magnesium manganese color coated board, printing color coated board, etc.

The varieties that can be produced are: ordinary building materials board, purification board, cold storage board, solar panel, door and window profile, household appliance board, writing board, printing board, reticulated suede color coating, embossed printing, aluminum magnesium manganese color coating board, high weather resistance, silicon modification, self-cleaning board, heat reflection board, antibacterial board, acid and alkali resistant color coating board, etc., which can meet customer requirements of different industries and provide technical support and solutions.

Color Coated Galvalume Steel Sheet PPGL

Color-coated galvanized sheet PPGL is a hot-dip aluminum-zinc plate as the substrate, after surface pretreatment, roller coating method, coated with one or more layers of liquid coating, after baking and cooling, the surface is rich in color, good weather resistance, superior processing performance.

Color coated board can be divided into ordinary PE, high corrosion resistant HDP, high corrosion resistant silicon modified polyester SMP, high corrosion resistant fluorocarbon PVDF, super corrosion resistant nano fluorocarbon PVDF, aluminum magnesium manganese color coated board, printing color coated board, etc.

The varieties that can be produced are: ordinary building materials board, purification board, cold storage board, solar panel, door and window profile, household appliance board, writing board, printing board, reticulated suede color coating, embossed printing, aluminum magnesium manganese color coating board, high weather resistance, silicon modification, self-cleaning board, heat reflection board, antibacterial board, acid and alkali resistant color coating board, etc., which can meet customer requirements of different industries and provide technical support and solutions.

Color Coated Galvalume Steel Sheet PPGL

Color-coated galvanized sheet PPGL is a hot-dip aluminum-zinc plate as the substrate, after surface pretreatment, roller coating method, coated with one or more layers of liquid coating, after baking and cooling, the surface is rich in color, good weather resistance, superior processing performance.

Color coated board can be divided into ordinary PE, high corrosion resistant HDP, high corrosion resistant silicon modified polyester SMP, high corrosion resistant fluorocarbon PVDF, super corrosion resistant nano fluorocarbon PVDF, aluminum magnesium manganese color coated board, printing color coated board, etc.

The varieties that can be produced are: ordinary building materials board, purification board, cold storage board, solar panel, door and window profile, household appliance board, writing board, printing board, reticulated suede color coating, embossed printing, aluminum magnesium manganese color coating board, high weather resistance, silicon modification, self-cleaning board, heat reflection board, antibacterial board, acid and alkali resistant color coating board, etc., which can meet customer requirements of different industries and provide technical support and solutions.

Color Coated Galvalume Steel Sheet PPGL

Color-coated galvanized sheet PPGL is a hot-dip aluminum-zinc plate as the substrate, after surface pretreatment, roller coating method, coated with one or more layers of liquid coating, after baking and cooling, the surface is rich in color, good weather resistance, superior processing performance.

Color coated board can be divided into ordinary PE, high corrosion resistant HDP, high corrosion resistant silicon modified polyester SMP, high corrosion resistant fluorocarbon PVDF, super corrosion resistant nano fluorocarbon PVDF, aluminum magnesium manganese color coated board, printing color coated board, etc.

The varieties that can be produced are: ordinary building materials board, purification board, cold storage board, solar panel, door and window profile, household appliance board, writing board, printing board, reticulated suede color coating, embossed printing, aluminum magnesium manganese color coating board, high weather resistance, silicon modification, self-cleaning board, heat reflection board, antibacterial board, acid and alkali resistant color coating board, etc., which can meet customer requirements of different industries and provide technical support and solutions.

Color Coated Galvalume Steel Sheet PPGL

Color-coated galvanized sheet PPGL is a hot-dip aluminum-zinc plate as the substrate, after surface pretreatment, roller coating method, coated with one or more layers of liquid coating, after baking and cooling, the surface is rich in color, good weather resistance, superior processing performance.

Color coated board can be divided into ordinary PE, high corrosion resistant HDP, high corrosion resistant silicon modified polyester SMP, high corrosion resistant fluorocarbon PVDF, super corrosion resistant nano fluorocarbon PVDF, aluminum magnesium manganese color coated board, printing color coated board, etc.

The varieties that can be produced are: ordinary building materials board, purification board, cold storage board, solar panel, door and window profile, household appliance board, writing board, printing board, reticulated suede color coating, embossed printing, aluminum magnesium manganese color coating board, high weather resistance, silicon modification, self-cleaning board, heat reflection board, antibacterial board, acid and alkali resistant color coating board, etc., which can meet customer requirements of different industries and provide technical support and solutions.

Color Coated Galvalume Roof Sheet PPGL

PPGL roof panels are an excellent building material. Its weight is only 1/30 of the traditional concrete roof, which is easy to install and greatly shortens the construction period. It also maintains the strength and durability of the steel, allowing it to last more than 25 years under normal conditions. In addition, it is beautiful and generous, with various colors, patterns and patterns, which can meet different architectural styles. More importantly, PPGL steel has excellent heat resistance, which makes it an ideal roofing material even in hot climates. Whether it is home or investment, PPGL roof panels will be a good choice.

Color Coated Galvanized Roof Sheet PPGI

PPGI roof panels are beautiful and durable to meet your agricultural, residential and commercial needs. PPGI roof panels are available in a variety of different designs and sizes. Available thickness is 0.2 to 0.8mm, width is 600 to 1,250mm. In addition, colors and patterns are customizable.

Color Coated Galvalume Steel Sheet PPGL Description

Corrugated color roof is a lightweight, strong, anti-corrosion building material. It is made of color-coated steel plate and designed in different styles, such as wavy, trapezoidal rib, tile, etc. In addition, our corrugated steel roof panels are available in many colors and sizes. Not only that, we also provide customized solutions to better meet your needs. Our color coated roof panels are suitable for many applications, such as garages, industrial workshops, agricultural buildings, barns, garden sheds, etc.

Color Coated Galvalume Steel Sheet PPGL

Color-coated galvanized sheet PPGL is a hot-dip aluminum-zinc plate as the substrate, after surface pretreatment, roller coating method, coated with one or more layers of liquid coating, after baking and cooling, the surface is rich in color, good weather resistance, superior processing performance.

Color coated board can be divided into ordinary PE, high corrosion resistant HDP, high corrosion resistant silicon modified polyester SMP, high corrosion resistant fluorocarbon PVDF, super corrosion resistant nano fluorocarbon PVDF, aluminum magnesium manganese color coated board, printing color coated board, etc.

The varieties that can be produced are: ordinary building materials board, purification board, cold storage board, solar panel, door and window profile, household appliance board, writing board, printing board, reticulated suede color coating, embossed printing, aluminum magnesium manganese color coating board, high weather resistance, silicon modification, self-cleaning board, heat reflection board, antibacterial board, acid and alkali resistant color coating board, etc., which can meet customer requirements of different industries and provide technical support and solutions.

Color Coated Galvanized Steel Sheet PPGI

Color-coated galvanized sheet PPGI is based on hot-dip galvanized sheet, electro-galvanized sheet, etc. as the substrate, after surface pretreatment, roller coating method, coated with one or more layers of liquid coating, after baking and cooling, the surface is rich in color, has good weather resistance, superior processing performance.

G90 refers to the coating type and coating weight on the steel coil or steel plate. "G" means that the coating is galvanized, that is, galvanized. Meanwhile, the number "90" represents the weight of zinc on the steel. G90 galvanized steel coil is hot-dip galvanized cold-rolled steel sheet to improve durability.

G60 is the coating grade of steel sheet after continuous hot dip plating process. G represents the "galvanized" or galvanized layer of the product. The number 60 refers to the thickness of the zinc around the steel sheet or the thickness of the entire double-sided coating. To get the amount of galvanizing on one side, you need to divide this number by two.

Galvanized steel sheet G60 is coated with molten zinc. After the continuous coating process at a speed of 600 feet per minute, the excess zinc on the steel plate is removed by high-pressure air. This is in order to produce the desired coating thickness. After cooling, the sheet is rolled into a roll, ready for manufacturing.