Product Categories

Contact Us

Add:Building 8, International Financial Center, Liaocheng Economic and Technological Development Zone, Shandong Province, China

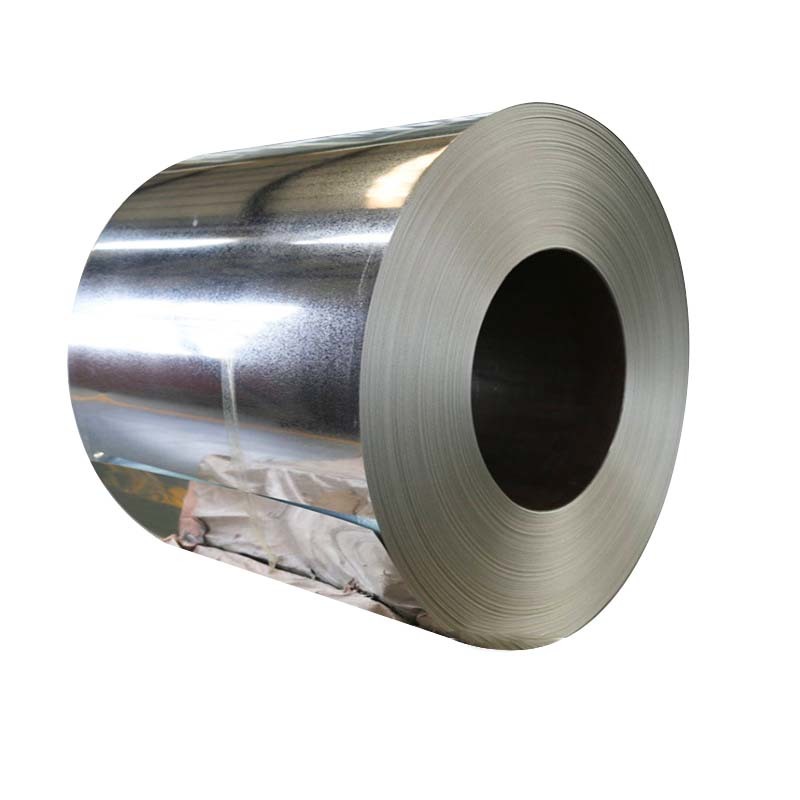

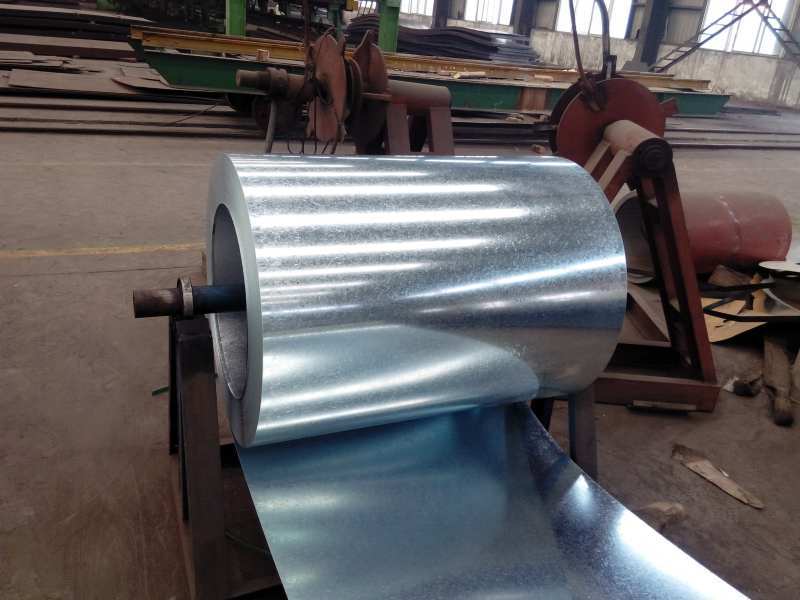

Hot Dip Galvanized Coil

Hot dip galvanizing is to make the molten metal react with the iron substrate to produce an alloy layer, so that the substrate and the coating are combined. Hot galvanizing is to pickle the steel and iron parts first. In order to remove the iron oxide on the surface of the steel and iron parts, after pickling, it is cleaned by ammonium chloride or zinc chloride aqueous solution or ammonium chloride and zinc chloride mixed aqueous solution tank, and then sent into the hot dip plating tank. Hot-dip galvanizing has the advantages of uniform coating, strong adhesion and long service life. Hot-dip galvanizing is one of the effective means to delay the environmental corrosion of iron and steel materials, it is the surface of the cleaned, activated iron and steel products immersed in molten zinc, through the reaction and diffusion between iron and zinc, in the iron and steel products surface plating good adhesion of zinc alloy coating. Compared with other metal protection methods, the hot-dip galvanizing process has advantages in the protection characteristics of the combination of physical barrier and electrochemical protection of the coating, the bonding strength of the coating and the substrate, the compactness, durability, maintenance-free and economy of the coating, and its adaptability to the shape and size of the product. At present, hot-dip galvanized products mainly include steel plates, steel strips, steel wires, steel pipes, etc., of which hot-dip galvanized steel plates account for a large proportion.

Keywords:

Description

Hot Dip Galvanized Coil Description

Hot dip galvanizing is to make the molten metal react with the iron substrate to produce an alloy layer, so that the substrate and the coating are combined. Hot galvanizing is to pickle the steel and iron parts first. In order to remove the iron oxide on the surface of the steel and iron parts, after pickling, it is cleaned by ammonium chloride or zinc chloride aqueous solution or ammonium chloride and zinc chloride mixed aqueous solution tank, and then sent into the hot dip plating tank. Hot-dip galvanizing has the advantages of uniform coating, strong adhesion and long service life.

Hot-dip galvanizing is one of the effective means to delay the environmental corrosion of iron and steel materials, it is the surface of the cleaned, activated iron and steel products immersed in molten zinc, through the reaction and diffusion between iron and zinc, in the iron and steel products surface plating good adhesion of zinc alloy coating. Compared with other metal protection methods, the hot-dip galvanizing process has advantages in the protection characteristics of the combination of physical barrier and electrochemical protection of the coating, the bonding strength of the coating and the substrate, the compactness, durability, maintenance-free and economy of the coating, and its adaptability to the shape and size of the product. At present, hot-dip galvanized products mainly include steel plates, steel strips, steel wires, steel pipes, etc., of which hot-dip galvanized steel plates account for a large proportion.

The production process of hot galvanizing is as follows:

Mother material → degreasing → water washing → pickling → water washing → rinsing → flux solution → drying → hot galvanizing → cooling → inspection → packaging

Scope of Application

For a long time, hot-dip galvanizing process has been favored by people because of its low plating cost, excellent protection characteristics and beautiful appearance. It is widely used in automobile, construction, household appliances, chemical industry, machinery, petroleum, metallurgy, light industry, transportation, electric power, aviation and marine engineering and other fields.

Product Parameters

|

Product name |

Hot Dip Galvanized Coil |

|

Grade |

Q195 Q235 Q345 |

|

SGCC SGCH SGC340 SGC400 SGC440 SGC490 SGC570 |

|

|

SGHC SGH340 SGH400 SGH440 SGH490 SGH540 |

|

|

DX51D DX52D DX53D DX54D DX55D DX56D DX57D |

|

|

S220GD S250GD S280GD S320GD S350GD S400GD S500GD S550GD |

|

|

SS230 SS250 SS275 |

|

|

Thickness |

0.12mm-8.0mm |

|

Width |

700-1500mm |

|

Zinc coatin |

AZ40g/m2-AZ275g/m2 |

|

Painting |

Top side:10-25 microns, back side 5-10 microns |

|

Spangle |

No spangle , min spangle , regular spangle |

|

Standard |

ASTM AISI JIS DNS GB etc |

|

Package |

Mill standard export seaworthy packing |

|

Application |

Roofing sheets, construction, door and windows, solar heater, cold room,kitchen utensils, household appliance etc. |

|

Payment terms |

L/C , T/T , Cash , DA,DP Alibaba.com Trade Assurance |

|

Inspection |

Factory Inspection certificate will be issued for every shipments. |

Product Specifications

|

Type |

Thickness(mm) |

Width(mm) |

|||

|

1219 |

1500 |

1800 |

2000 |

||

|

Cold Rolled |

0.3 |

√ |

√ |

√ |

√ |

|

0.4 |

√ |

√ |

√ |

√ |

|

|

0.5 |

√ |

√ |

√ |

√ |

|

|

0.6 |

√ |

√ |

√ |

√ |

|

|

0.7 |

√ |

√ |

√ |

√ |

|

|

0.8 |

√ |

√ |

√ |

√ |

|

|

0.9 |

√ |

√ |

√ |

√ |

|

|

1.0 |

√ |

√ |

√ |

√ |

|

|

1.2 |

√ |

√ |

√ |

√ |

|

|

1.5 |

√ |

√ |

√ |

√ |

|

|

1.8 |

√ |

√ |

√ |

√ |

|

|

2.0 |

√ |

√ |

√ |

√ |

|

|

2.5 |

√ |

√ |

√ |

√ |

|

|

3.0 |

√ |

√ |

√ |

√ |

|

|

4.0 |

√ |

√ |

√ |

√ |

|

|

5.0 |

√ |

√ |

√ |

√ |

|

|

6.0 |

√ |

√ |

√ |

√ |

|

|

Hot Rolled |

4.0 |

√ |

√ |

√ |

√ |

|

5.0 |

√ |

√ |

√ |

√ |

|

|

6.0 |

√ |

√ |

√ |

√ |

|

|

8.0 |

√ |

√ |

√ |

√ |

|

|

10.0 |

√ |

√ |

√ |

√ |

|

|

12.0 |

√ |

√ |

√ |

√ |

|

|

14.0 |

√ |

√ |

√ |

√ |

|

|

16.0 |

√ |

√ |

√ |

√ |

|

| Product Details | Product Production | Product Warehouse |

|

|

|

|

|

|

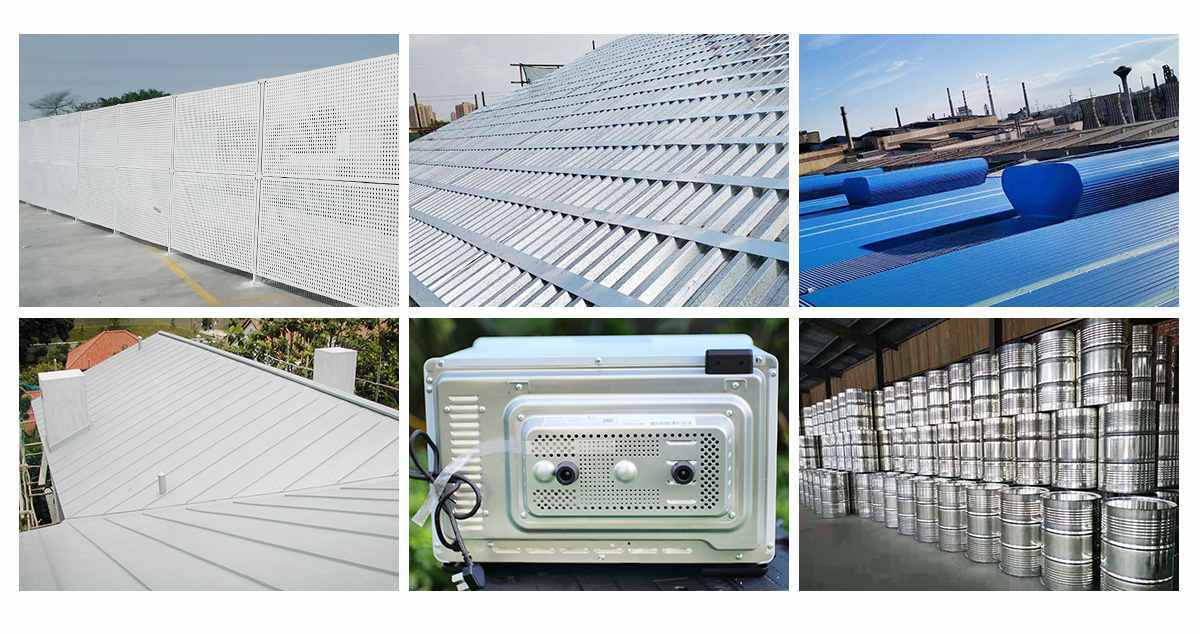

Applications

The Galvanized Steel coil is mainly used in industries such as construction, light industry, automobiles, agriculture, animal husbandry, fishery, and commerce.

The construction industry is mainly used for manufacturing anti-corrosion industrial and civil building roof panels, roof grilles, etc.

Light industry uses it to manufacture home appliance shells, civilian chimneys, kitchen utensils, etc.

The automotive industry is mainly used for manufacturing corrosion-resistant components of automobiles.

Agriculture and animal husbandry are mainly used for food storage and transportation, as well as tools for freezing and processing meat and aquatic products.

Project Cases

Additional Processing Technology

Galvanized sheet and coil can be processed through various processes such as cutting, welding, punching, and pressing, and the size of zinc flakes can be selected.

Product Packaging

Product Transportation

Corporate Honor

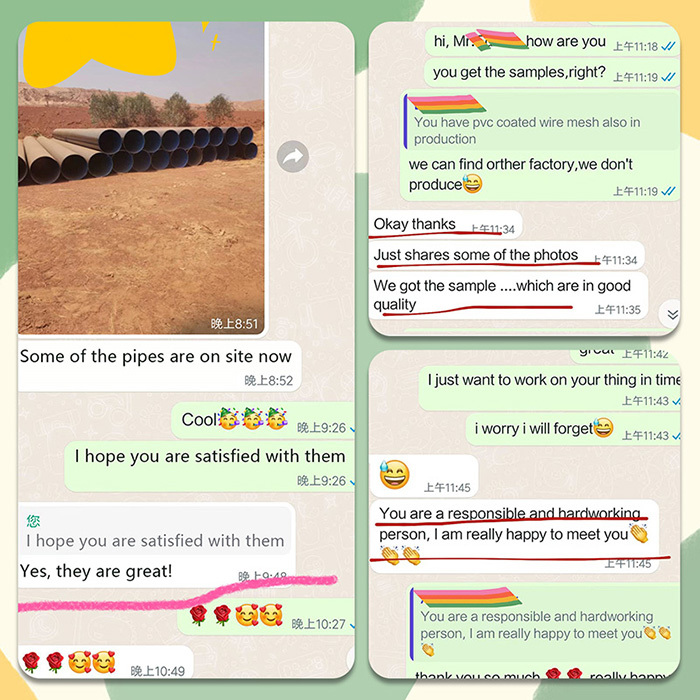

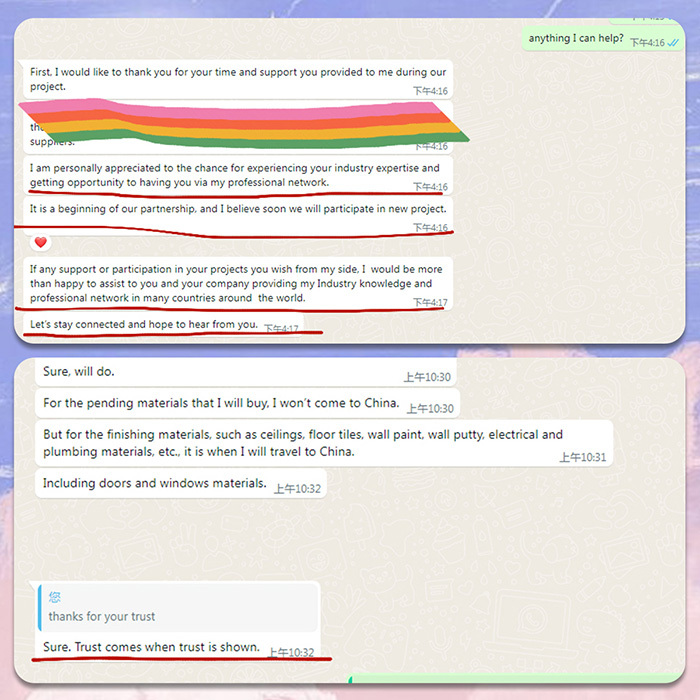

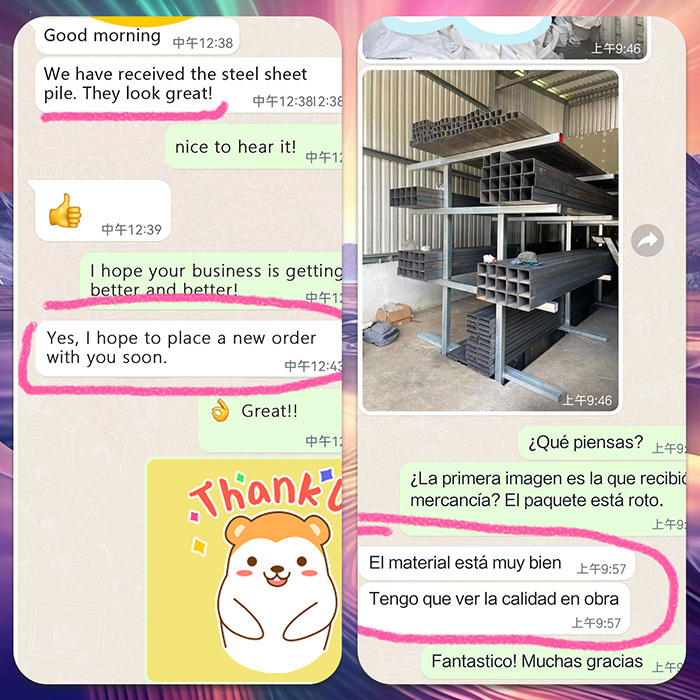

Client Feedback

FAQ

...

Get a free quote

Please fill in the contact information with your needs, we will arrange a professional to contact you!