Categories

Steel Plate

ASTM A283 is a carbon steel plate used for general structural purposes. The steel has low and medium tensile strength. The ASTM A283 steel specification covers four structural quality grades of mild steel, grades A, B, C, and D, for general application.

A36/Q235/S235JR Carbon Steel Plate

A36 is a low-carbon steel containing trace amounts of manganese, phosphorus, sulfur, silicon and other elements such as copper. A36 has good weldability and high yield strength, and is the structural steel plate specified by the engineer. ASTM A36 steel plate is often manufactured into a variety of structural steel parts. This grade is used for welded, bolted or riveted construction of bridges and buildings, as well as for general structural purposes. Due to its low yield point, A36 carbon plate can be used to design lighter weight structures and equipment, and provide good weldability. Construction, energy, heavy equipment, transportation, infrastructure and mining are the industries where A36 panels are commonly used.

ASTM A633 steel includes four grades: A, C, D, and E, of which the thickness of grade C can reach 4 inches and the thickness of grade E can reach 6 inches. ASTM A633 steel specification is based on the standard specification for standardized high-strength low-alloy structural steel plate, which requires high notch toughness under low temperature conditions.

Carbon steel plate is a rectangular plate made of non-alloy material mainly composed of iron and carbon. In addition to carbon, it also contains a small amount of silicon, manganese, sulfur, phosphorus and other elements. The higher the carbon content, the better the hardness and the better the strength. Due to its good mechanical properties and plasticity, it is widely used in various fields.

Wear-resistant plate is a material with excellent wear resistance and is commonly used in components and equipment that require wear resistance in various industrial fields. It can effectively extend the service life of equipment, reduce the frequency of maintenance and replacement, and improve production efficiency.

Weathering board, also known as steel plastic composite board, is a composite material composed of plastic and carbon steel plates. Its main characteristics are strong weather resistance, resistance to harsh weather environments, and good heat and corrosion resistance. It is widely used in construction, automotive, electrical, and other industries due to its ability to resist the effects of ultraviolet radiation, humidity changes, and other environmental factors.

Boiler plate is a hot-rolled medium-thick plate material used to manufacture superheaters, main steam pipes and boiler firebox heating surfaces. Since the boiler steel plate works under medium temperature (below 350oC) and high pressure, in addition to bearing high pressure, it is also subject to impact, fatigue load and water and gas corrosion. The performance requirements for boiler steel are mainly good welding and cold bending properties. Certain high temperature strength and resistance to alkali corrosion, oxidation, etc.

Carbon steel plate is a rectangular plate made of non-alloy material mainly composed of iron and carbon. In addition to carbon, it also contains a small amount of silicon, manganese, sulfur, phosphorus and other elements. The higher the carbon content, the better the hardness and the better the strength. Due to its good mechanical properties and plasticity, it is widely used in various fields.

Galvanized coils are materials produced through a continuous hot-dip galvanizing process using hot-rolled steel strips or cold-rolled steel strips as the base plate. Hot-dip galvanized sheets are supplied as rectangular flat sheets after cross-cutting; hot-dip galvanized coils are supplied as rolls after being rolled.

Their main characteristics are: strong corrosion resistance, good surface quality, conducive to deep processing, economical and practical, etc.

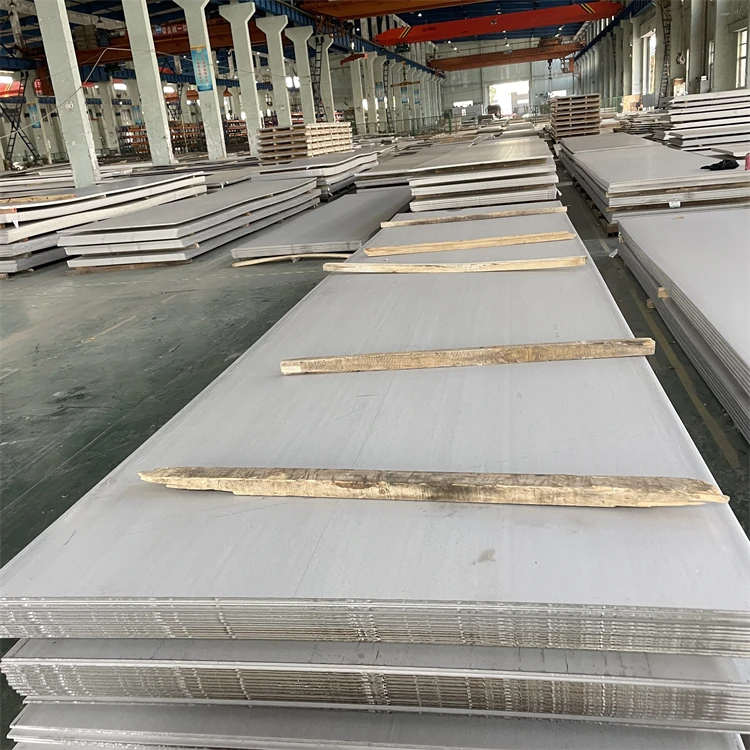

Stainless steel is initially produced in slabs, which are then put through a conversion process using a Z mill, which converts the slab into coil prior to further rolling. These wide coils are typically made at around 1250mm (sometimes a little wider) and are known as 'mill edge coils'. After the stainless steel roll is rolled flat, it becomes a stainless steel sheet(plate).