Product Categories

Contact Us

Add:Building 8, International Financial Center, Liaocheng Economic and Technological Development Zone, Shandong Province, China

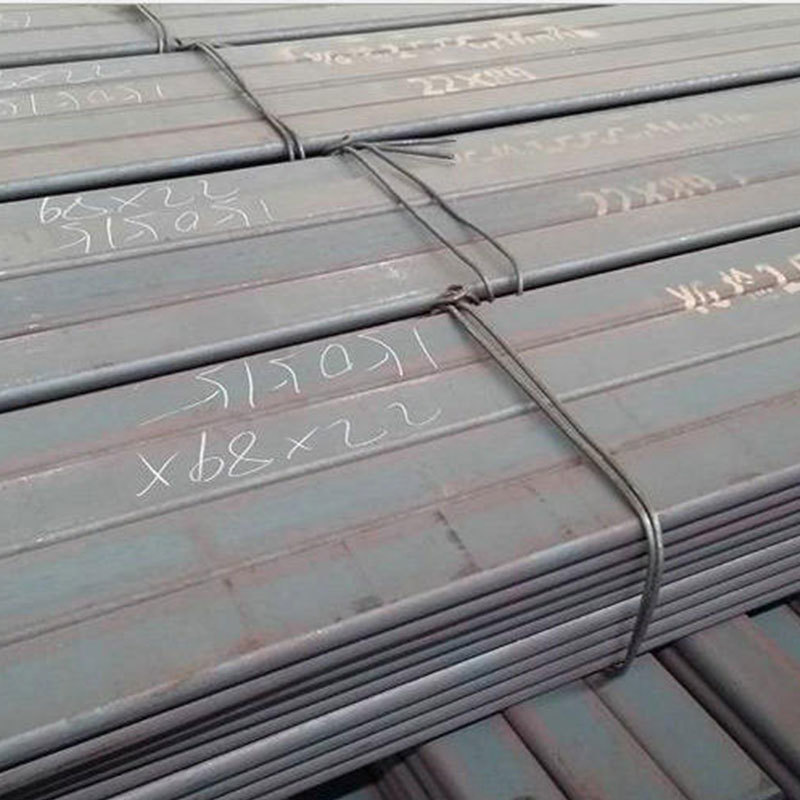

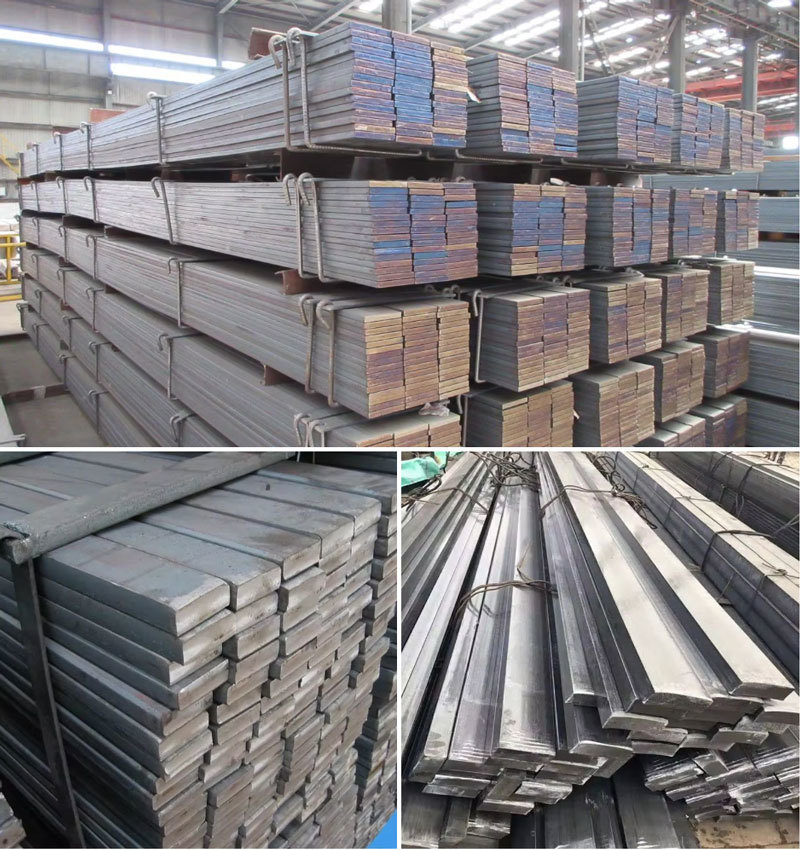

Alloy flat steel bars

Keywords:

Description

Product descriptions from the supplier

Tool steel

Tool steel can be classified according to chemical composition and use, mainly including the following categories:

Carbon tool steel: This type of steel has a high carbon content, usually between 0.65% and 1.35%. Carbon tool steel has high hardness and wear resistance, but poor red hardness, and is suitable for tools that require high hardness and wear resistance, such as hammers, chisels, etc.

Alloy tool steel: Alloy elements such as chromium, molybdenum, and tungsten are added to carbon tool steel to improve hardenability and hardness. Alloy tool steel is suitable for high-speed cutting tools, molds and other fields, with higher hardness and wear resistance.

High-speed steel: Contains a variety of alloy elements such as tungsten, molybdenum, and cobalt, has extremely high hardness and wear resistance, and is suitable for high-speed cutting tools and forging molds.

Stainless steel: It has excellent corrosion resistance and is suitable for molds, knives, bearings and other fields.

Specific application scenarios of different types of tool steel include:

Carbon tool steel: Such as T10A, suitable for hand tools such as hammers and chisels.

Alloy tool steel: such as SKD11, widely used in large cold working dies and various cold working dies, as well as cutting tools.

High speed tool steel: such as W18Cr4V, suitable for high speed cutting tools.

Stainless steel: such as 3Cr13, suitable for dies and cutting tools.l properties, such as stainless steel, heat-resistant steel and wear-resistant steel, etc.

Products Description

|

steel type |

Main production varieties |

|||||

|

China |

USA |

Germany |

Japan |

Swede |

||

|

steel grade |

material grade |

|||||

|

Cold Work |

Cr12 |

D3 |

X210Cr12 |

1.2080 |

SKD1 |

HW-5 |

|

Cr12HoV |

|

X165CrMoV12 |

1.2601 |

|

2310 |

|

|

Cr12No1V1 |

D2 |

X155CrVHo12-1 |

1.2379 |

SKD11 |

XW-4 |

|

|

9CrWNn |

01 |

100NnCrW4 |

1.2510 |

SKS3 |

2140 |

|

|

Cr5Mo1V |

A2 |

X100CrMoV5 |

1.2363 |

SKD12 |

XW-40 |

|

|

9Mn2V |

02 |

90MnCrV8 |

1.2842 |

|

|

|

|

42CrMo |

|

40CrHnNoS8-6 |

1.2312 |

|

|

|

|

Cr8No2VSi |

|

|

|

Dc53 |

88 |

|

|

5Cr5WHoVSi |

A8 |

|

|

|

|

|

|

Cr12M |

D6 |

X210Cr12 |

1.2436 |

|

|

|

|

Hot Work |

4Cr5MoSiV |

H11 |

X38CrMoV5-1 |

1.2343 |

SKD6 |

|

|

4Cr5NoSiV1 |

H13 |

X40CrMoV5-1 |

1.2344 |

SKD61 |

8407 |

|

|

3Cr2W8V |

H21 |

X30WCrV9-3 |

1.2581 |

SKD5 |

2730 |

|

|

5CrMnNo |

|

40CrMnMo7 |

1.2311 |

SKT3 |

|

|

|

5CrNiMo |

L6 |

55NiCrHoV6 |

1.2713 |

SKT4 |

2550 |

|

|

4Cr3No3Siv |

H10 |

32CrMoV12-28 |

1.2365 |

|

|

|

|

5CrNiNoV |

|

56NiCrNoV7 |

1.2714 |

|

|

|

|

|

|

X45NiCrMo4 |

1.2767 |

|

|

|

|

Plastic Mould |

3Cr2No |

P20 |

35CrMo4 |

1.2330 |

|

618 |

|

3Cr2NiMnMo |

P20+Ni |

40CrMnMo7 |

1.2738 |

|

718 |

|

|

10Ni3MnCuAi |

|

|

|

NAK80 |

|

|

|

4Cr13 |

420 |

|

1.2083 |

SUS420 |

S136 |

|

|

3Cr17NiMo |

|

X36CrHo17 |

1.2316 |

|

|

|

|

High Speed Steel |

W18Cr4V |

T1 |

S18-1 |

1.3355 |

SKH2 |

2750 |

|

N6No5Cr4V2 |

M2 |

S6-5-2 |

1.3343 |

SKH51 |

2722 |

|

|

W9m03Cr4V |

|

|

|

|

|

|

|

Stainless Steel |

9Cr18Mo |

440C |

X105CrNo17 |

1.4125 |

SUS440C |

|

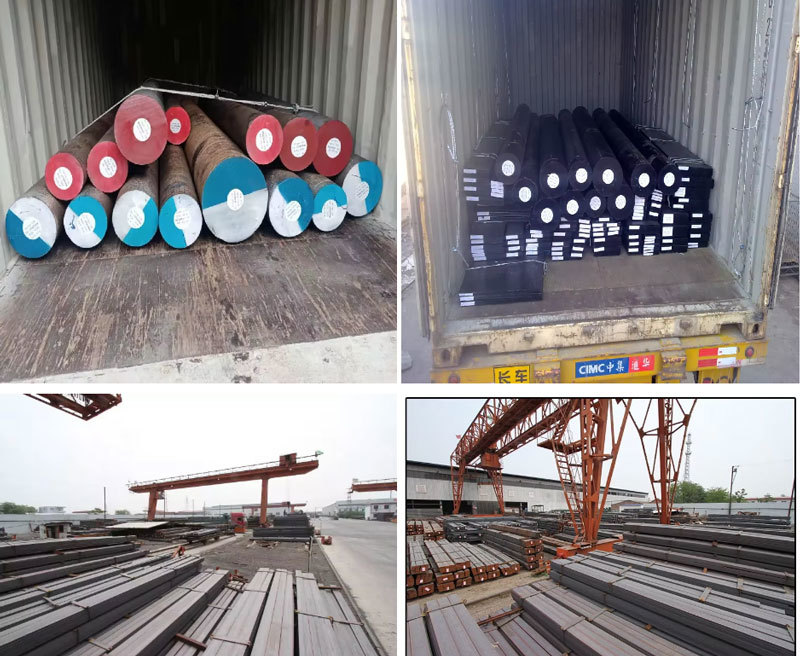

Product Show

packaging and shipping

Corporate Honor

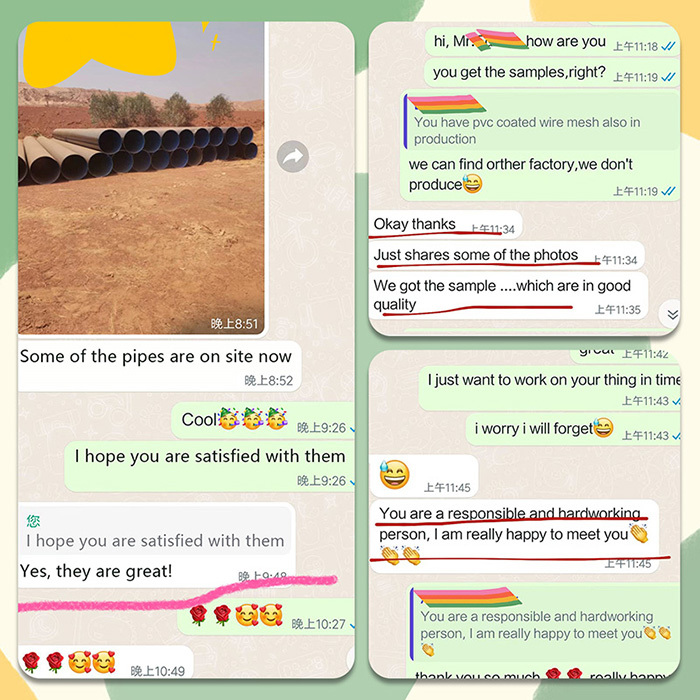

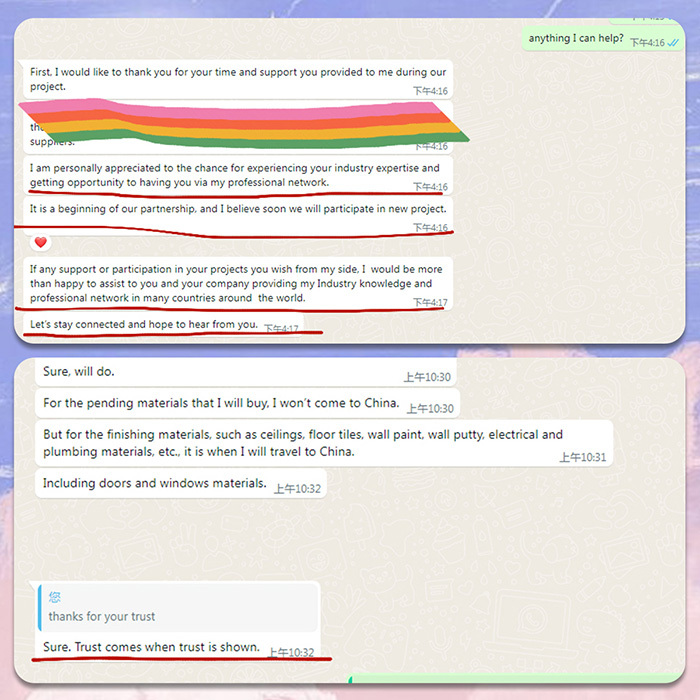

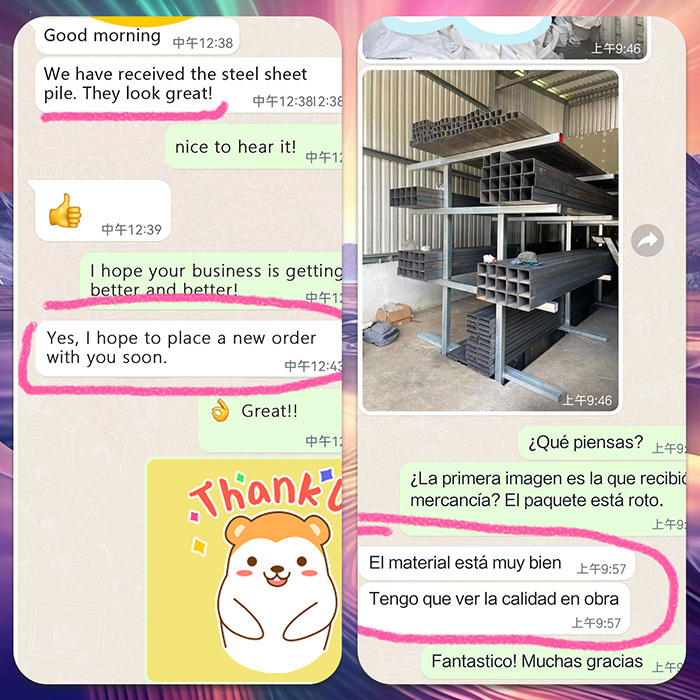

Client Feedback

FAQ

...

Get a free quote

Please fill in the contact information with your needs, we will arrange a professional to contact you!