Product Categories

Contact Us

Add:Building 8, International Financial Center, Liaocheng Economic and Technological Development Zone, Shandong Province, China

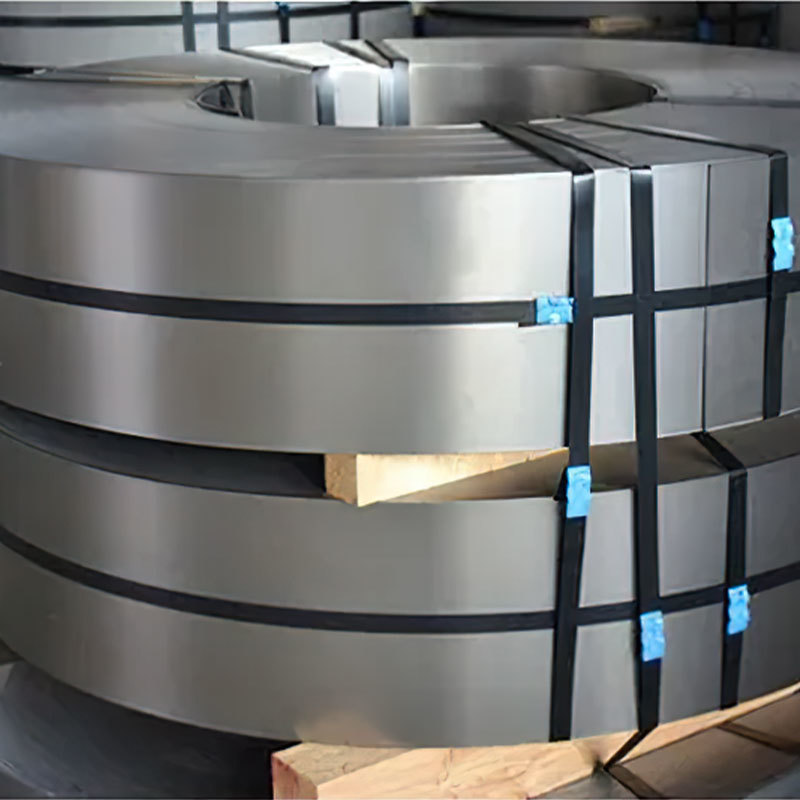

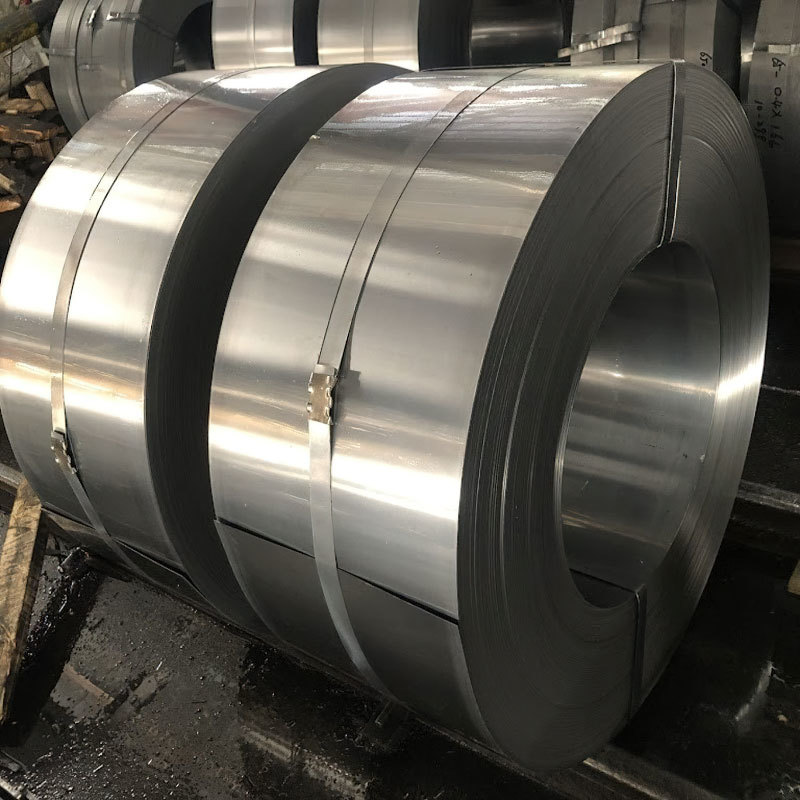

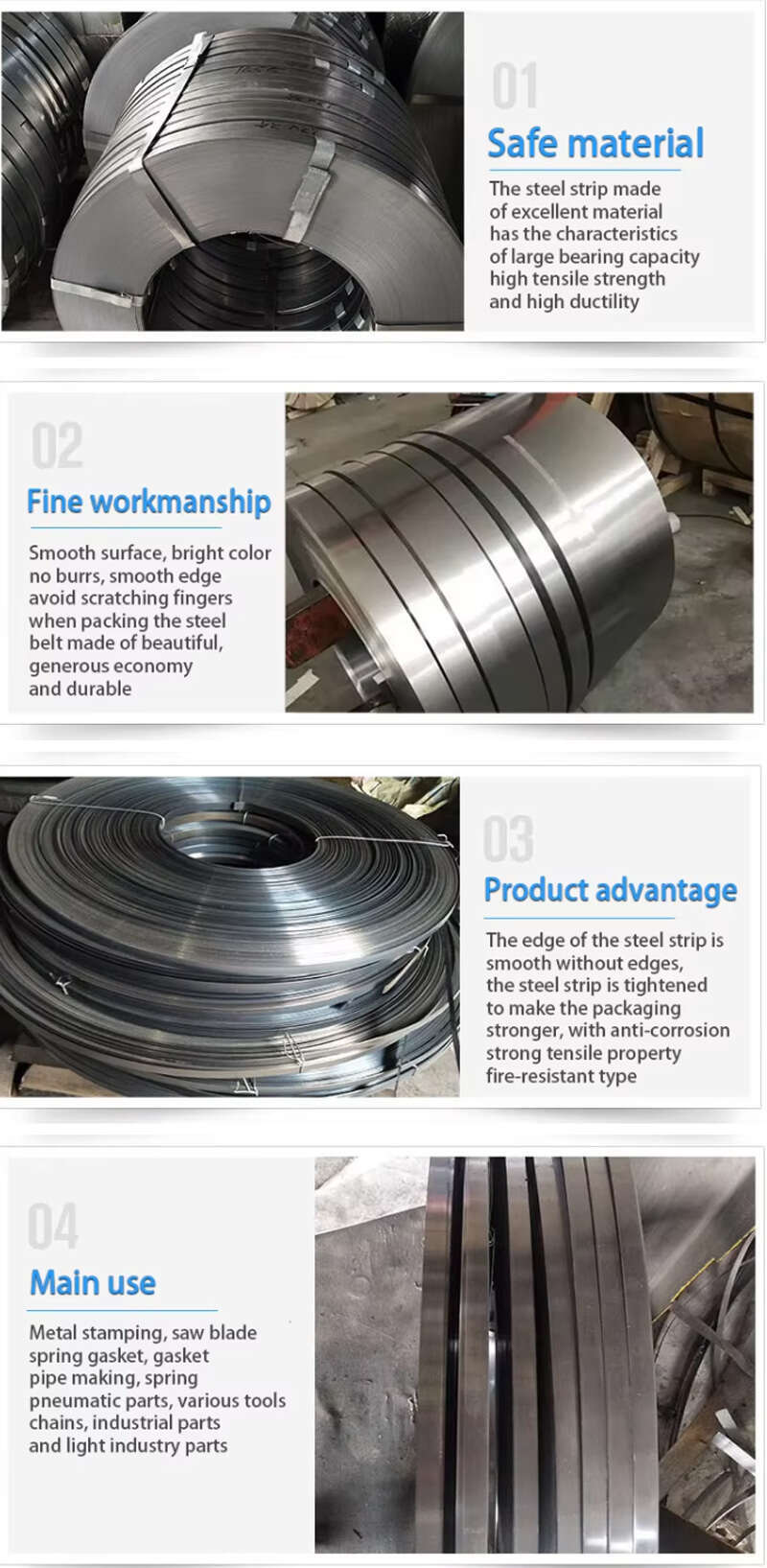

Spring Steel 65Mn Cold Rolled Steel Strip Slit Coils

Cold-rolled strip steel has various product specifications, high dimensional accuracy, good surface quality, and better mechanical and process properties than hot-rolled strip steel. Therefore, it is widely used in industrial sectors such as machinery manufacturing, automobile manufacturing, building structures, electronic instruments and household appliances.

Keywords:

Description

Supplier's product description

Product Description

Cold-rolled strip steel is a metallic material produced by cold rolling hot-rolled strip steel at room temperature. It typically has a thickness of 0.1–3 mm and a width of 100–2000 mm, and is characterized by high surface finish, good dimensional accuracy, and excellent mechanical properties. Product forms include coils, coated steel sheets, carbon structural steel, stainless steel, and electrical steel, and it is widely used in machinery manufacturing, the automotive industry, home appliance production, and building decoration. The production process includes pickling, cold rolling, annealing, and finishing. Quality is ensured by controlling parameters such as reduction and tension, and a leveling process is used to improve sheet shape and performance.

Main Applications of Cold-Rolled Steel Strip

The applications of cold-rolled steel strip can be categorized into the following main types based on its final form and function:

1. Structural Components and General Parts

This category has basic requirements for the strength and formability of the steel strip and represents the largest application area.

Examples of applications: Furniture frames, filing cabinets, appliance housings, brackets, lighting fixtures, various hardware components, etc.

Performance requirements: Good stamping formability, sufficient strength and rigidity, and a smooth surface.

2. Automotive Manufacturing

The automotive industry is a major user of high-quality cold-rolled steel strip, with extremely high requirements for safety, lightweight design, and formability.

Examples of applications:

Body panels: Doors, hoods, trunk lids, etc., requiring extremely high formability and surface quality.

Structural components: Chassis parts, reinforcements, crash beams, etc., requiring high strength and high impact resistance.

Performance requirements: Deep drawing performance, high strength (especially advanced high-strength steel/AHSS), and fatigue resistance.

3. Home Appliances Home appliances have high requirements for appearance and durability.

Examples of applications: Inner and outer casings, panels, and structural components of refrigerators, washing machines, air conditioners, and microwave ovens.

Performance requirements: Good paintability, surface quality (defect-free), formability, and corrosion resistance (often using galvanized steel).

4. Precision Electronics and Instruments This type of application has very stringent requirements for the thickness accuracy, surface finish, and uniformity of the steel strip.

Examples of applications: Metal casings for mobile phones/computers, shielding covers, connectors, spring sheets, precision instrument parts, chip lead frames, etc.

Performance requirements: Extremely high dimensional accuracy, excellent surface finish, specific electrical/magnetic conductivity, and good elasticity.

5. Food Packaging and Containers The most common application is the manufacture of metal packaging cans.

Examples of applications: Aluminum cans (body and lid), food cans, aerosol cans, metal bottle caps, dry cell battery casings, etc.

Performance Requirements: Extremely thin thickness, extremely high formability (deep drawing, thinning and stretching), corrosion resistance, and food safety.

6. Other Specialized Applications

Saw Blades and Blades: Requires high hardness and wear resistance.

Architectural Decoration: Such as light steel keel, ceilings, etc.

Enamel Products: Requires good adhesion between the steel strip and the enamel glaze.

Product Name | Carbon structural steel, alloy and low alloy steel, stainless steel, electrical steel and other special steel strips, etc. |

Width | 30-600mm Or we can customize the size according to customer requirements. |

Thickness | 0.12-4.0mm Or we can customize the size according to customer requirements. |

Tolerance | Thickness and width: +/-0.02mm |

Common material grades | DC01、DC03、DC04、DC05、DC06、DC07 SPCC、SPCD、SPCE、SPCEN CS、DS、DDS、EDDS C75、C75S、65Mn、ST12、ST13、ST14、ST15、ST16 201、304、316L、321、444、430、420、410、439、347H、2205、2507、C-276、625、825、400、500、718 NAS 185N(254SMO)、NAS 254N、NAS 254NM(AL6XN) ASTM: HSLAS Grade 50/60, DP 450/600 |

Surface | Passivation, grease liquefaction, anti-stripping paint |

Hardness | HRB50-71 (CQ grade), HRB45-55 (DQ grade) or according requirements |

Tensile strength | 270-500 (CQ grade), 270-420 (DQ grade) |

Yield strength | 140-300 (DQ grade) |

Surface treatment | Passivation (C), oiling (O), paint sealing (L), phosphate coating (P), untreated (U) |

Surface structure | Normal gloss coating (NS), reduced gloss coating (MS), dull coating (FS) |

Packaging | Customer requirements or shipping arrangements |

Our advantages | One-stop purchasing; high quality; competitive price; on-time delivery; technical support; supply of materials and test reports; |

Notice | Please inform us of the size, quantity, material or grade, and surface. If it is a special, non-standard product, please provide drawings, photos, or samples. |

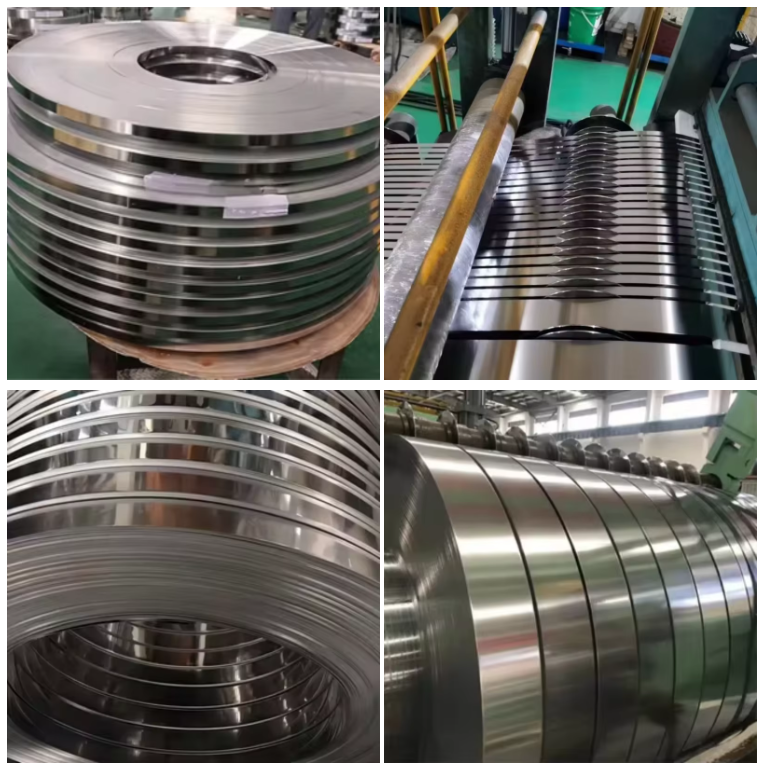

Detailed image

Products

Packaging and shipping

Corporate Honor

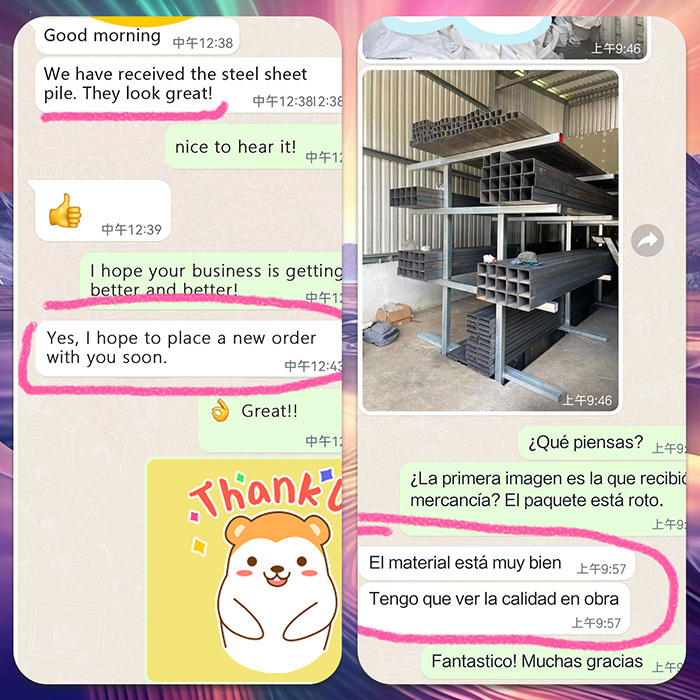

Client Feedback

FAQ

...

Get a free quote

Please fill in the contact information with your needs, we will arrange a professional to contact you!