Product Categories

Contact Us

Add:Building 8, International Financial Center, Liaocheng Economic and Technological Development Zone, Shandong Province, China

China factory supply silicon steel coils, strips, and sheets. Both oriented and non-oriented silicon steel are available.

Silicon steel is a silicon alloy steel containing 1.0–4.5% silicon and less than 0.08% carbon. It possesses characteristics such as high magnetic permeability, low coercivity, and high resistivity, resulting in low hysteresis and eddy current losses. It is mainly used as a magnetic material in motors, transformers, electrical appliances, and electrical instruments. To meet the requirements of punching and shearing processes during electrical manufacturing, a certain degree of plasticity is also required. To improve magnetic performance and reduce hysteresis losses, the content of harmful impurities should be as low as possible, and the sheet should be flat with good surface quality.

Keywords:

Description

Product Description- Silicon Steel

Silicon steel is a silicon alloy steel containing 1.0–4.5% silicon and less than 0.08% carbon. It possesses characteristics such as high magnetic permeability, low coercivity, and high resistivity, resulting in low hysteresis and eddy current losses. It is mainly used as a magnetic material in motors, transformers, electrical appliances, and electrical instruments. To meet the requirements of punching and shearing processes during electrical manufacturing, a certain degree of plasticity is also required. To improve magnetic performance and reduce hysteresis losses, the content of harmful impurities should be as low as possible, and the sheet should be flat with good surface quality.

Performance Requirements

The main performance requirements for silicon steel are:

1. Low iron loss: This is the most important indicator of silicon steel sheet quality. Different countries classify grades based on iron loss values; the lower the iron loss, the higher the grade.

2. High magnetic induction intensity (magnetic flux density) under strong magnetic fields. This allows for a reduction in the volume and weight of the iron core in motors and transformers, saving silicon steel sheets, copper wire, and insulation materials.

3. Smooth, flat, and uniform surface thickness: This improves the core filling coefficient.

4. Good stamping properties: This is especially important for manufacturing micro and small electric motors.

5. Good adhesion and weldability of the surface insulating film: This provides corrosion protection and improves stamping properties.

Production process

Pickling: Using a descaling machine and hydrochloric acid tank, oxides are removed from hot-rolled steel strip to prevent surface defects in cold-rolled finished products.

Cold Stamping: To ensure thickness and material for different applications, the reduction ratio is set between 40% and 90%, and advanced control equipment such as automatic thickness control and automatic shape control is implemented.

Annealing: This process softens the hardened steel strip material from the cold stamping process. Through metal heating and rapid cooling, steels for deep processing and high-tensile steels are produced, using box annealing (cover annealing) and continuous annealing methods.

Insulating Coating: When processing silicon steel sheets into iron cores, to improve their processing performance and prevent eddy current losses equivalent to the thickness of the steel sheet, an insulating coating liquid is sprayed onto both sides of the steel sheet using continuous coating equipment.

Product Categories

| Category | Silicon content /% | Nominal thickness/mm | Main uses | ||

| Hot-rolled silicon steel (non-oriented) | Hot-rolled low-silicon steel (motor steel) | 1.0~2.5 | 0.5 | Household motors and micro motors | |

| Hot-rolled high-silicon steel (transformer steel) | 3.0~4.5 | 0.35、0.50 | Transformer | ||

| Cold-rolled electrical steel | Cold-rolled non-oriented electrical steel (motor steel) | Low carbon electrical steel | ≤0.5 | 0.50、0.65 | Household motors, micro motors, small transformers, and ballasts |

| Silicon steel | >0.5~3.5 | 0.35、0.50 | Large and medium-sized motors, generators and transformers | ||

| Cold-rolled grain-oriented silicon steel (transformer steel) | Ordinary grain-oriented silicon steel | 2.9~3.3 | 0.18, 0.23, 0.27 0.30, 0.35 | Large, medium and small transformers and ballasts | |

| High magnetic induction grain-oriented silicon steel | |||||

| Special Purpose Silicon Steel: Cold-rolled Grain-Oriented Silicon Steel Strip | 2.9~3.3 | 0.03、0.05、0.10 | Pulse transformers, magnetic amplifiers, high-frequency transformers, and welding machines | ||

| Cold-rolled non-oriented silicon steel strip | 3.0 | 0.15、0.20 | High-frequency motors and generators | ||

| Cold-rolled non-oriented silicon steel for magnetic switches | 3.0 | 0.70 | Relays and magnetic switches | ||

| Cold-rolled high-silicon steel | 6.5 | 0.1~0.5 | High-frequency motors, transformers and magnetic shielding | ||

| Product Details | Product Production | Product Warehouse |

|  |  |

|  |  |

Product Packaging

Product Transportation

Corporate Honor

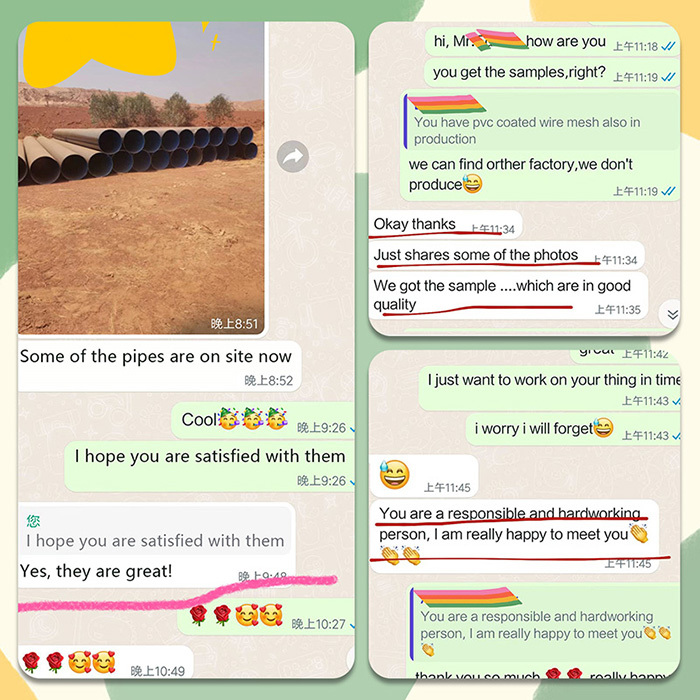

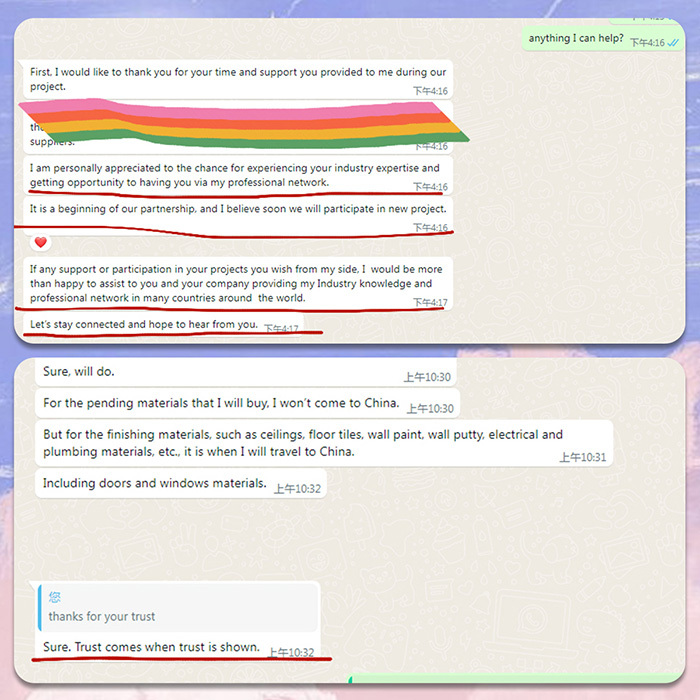

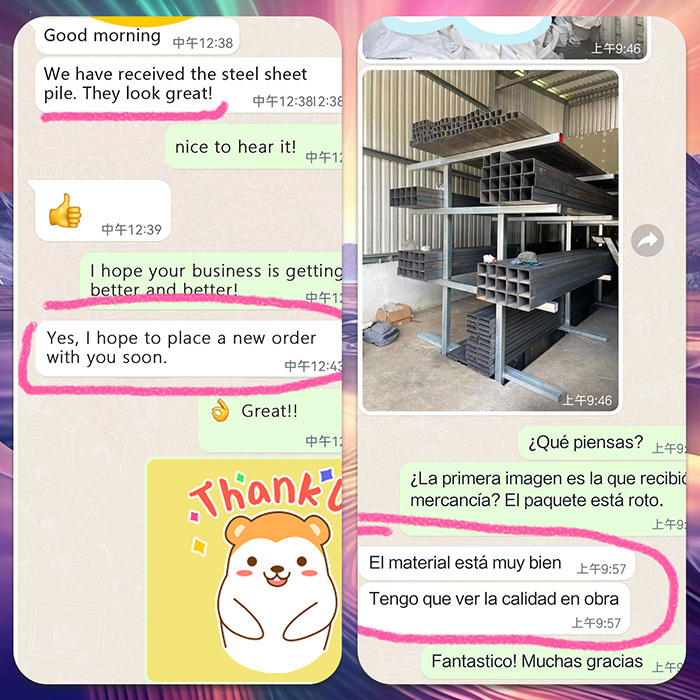

Client Feedback

FAQ

...

Get a free quote

Please fill in the contact information with your needs, we will arrange a professional to contact you!